What is Mica Capacitor?

Mica Capacitor is one kind of capacitor where the mica (silicate mineral) is used as a dielectric material that can be found in rocks, granites, etc. This material plays a key role in electrical applications like an electrical insulator. These components are reliable, stable, and high precision which is available from different ranges like low to high voltage, and mica capacitor capacitance range is from 20 pF – 10 µF. They are applicable where low capacitance & high accuracy changes over time are required. The efficient work of this type of capacitor can be done at high frequencies.

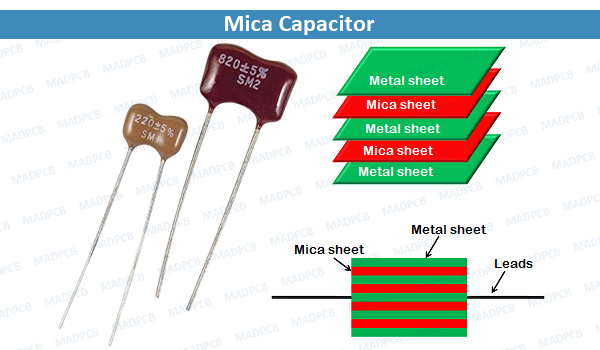

Mica Capacitor

In this capacitor, material like mica restricts the flow of current, so it can also be used in trimmer capacitors. The dielectric materials used in mica capacitor are white mica, muscovite, rose mica, amber mica, and ruby but from these three materials, muscovite mica material is used as a dielectric in mica capacitor manufacturing most frequently.

Mica Capacitor Construction

The construction of a mica capacitor can be done by inserting metal coated mica sheets one over another on both sides. After that, this construction can be covered within epoxy to protect it from the environment. The minerals of mica are electrically, mechanically & chemically stable due to the binding of its exact crystalline typical layered structure. The thin sheets of this capacitor can be designed with.025mm to 0.125 mm diameter.

The mica materials which are most frequently used are phlogopite mica & muscovite. The temperature resistance of phlogopite mica is high whereas the electrical properties of muscovite are better. Dielectric material like Mica is investigated in India, South America & Central Africa. In the composition of raw material, the high difference can lead to a high charge required for examination and categorization. Mica material doesn’t respond to most acids, oil, solvents & water.

Types of Mica Capacitor

Mica capacitors are classified into two types which include the following.

- Stacked Mica Capacitors: These capacitors are designed with thin mica sheets which are arranged one above another. The separation of every mica sheet can be divided through thin metal sheets of aluminum or copper. The whole unit can be enclosed within a plastic box to defend it from mechanical harm s well as moisture. The capacitor’s both the terminals are connected at every end of the capacitor where the mica sheets can be arranged among the metal sheets which work like a dielectric material. This material will oppose the current flow & aluminum or copper sheets perform like electrodes.

- Silvered Mica Capacitors: The construction of silvered mica capacitors can be done by coating with silver at any face of the mica sheets with the help of the screening method. In this capacitor, the required capacitance can be achieved through different mica sheets coated with silver. The arrangement of these sheets can be done one above the other. Here, the silver coat on top of the mica works like electrodes whereas mica sheets work like a dielectric. The properties of silvered mica capacitor include temperature coefficient, high accuracy, high Q, value range, low capacitance difference through voltage, etc. These types of capacitors are used in filters, coupling, decoupling, and RF oscillators.

Characteristics

Precision & Tolerance: The least amount of tolerance of the silver mica capacitor is ±1%. As compared to other capacitors, this is much better. In contrast, some ceramic capacitors have up to ±20% of tolerances.

Strength: These capacitors are accurate and stable, but their capacitance will change small eventually because there is no air gap within the design. The construction of this capacitor can be protected from moisture & other effects by electrical insulators like epoxy resin so that external effects do not influence these capacitors. The normal temperature coefficient is approximately 50 ppm/°C.

Low Losses: The losses of these capacitors are low inductive as well as resistive losses. Their characteristics are generally frequency-independent, so permits to use at high frequency. Silver mica capacitors are expensive & bulky.

Advantages

- Very accurate

- Capacitance is stable

- Works at high temperatures

- Resist at extremely high voltages

- Fewer losses

- Dielectric gives good insulation

Disadvantages

The disadvantages of the mica capacitor include the following.

- Expensive

- Appropriate sealing is necessary

Applications

The applications of the mica capacitor include the following.

- Silver mica capacitors are used in power RF circuits where stability is extremely important.

- These capacitors are used in tuned circuits with high frequency like oscillators and filters. Sometimes, they are utilized in snubbers.

- Silver mica capacitors are used widely in high-voltage applications because of the high breakdown voltage.

- These capacitors are used in high-power applications like RF transmitters.

- These capacitors are used in coupling circuits, resonance circuits, LASER, RADAR, space, etc.

Thus, this is all about an overview of mica capacitors, types, working, and applications. For many years, these capacitors are used in electronic industries. These components will provide extremely high operating reliability, low induction & stability in the long term. Additionally, the loss factor of these capacitors is almost frequency-independent & can be used in different applications. The applications of silver mica capacitors include coupling circuits, resonance circuits, TV amplifiers, power conversion circuits, radio, time constant circuits, RF transmitters, etc. Here is a question for you, what is Mica in mica capacitor?