Table of Contents

Rigid & Rigid-Flex PCB Fabrication Process

With advanced PCB manufacturing capabilities, MADPCB globally offers printed circuit board fabrication, providing high quality and reasonable price of printed circuit boards, including rigid PCB, MCPCB, flex PCB and rigid-flex PCB.

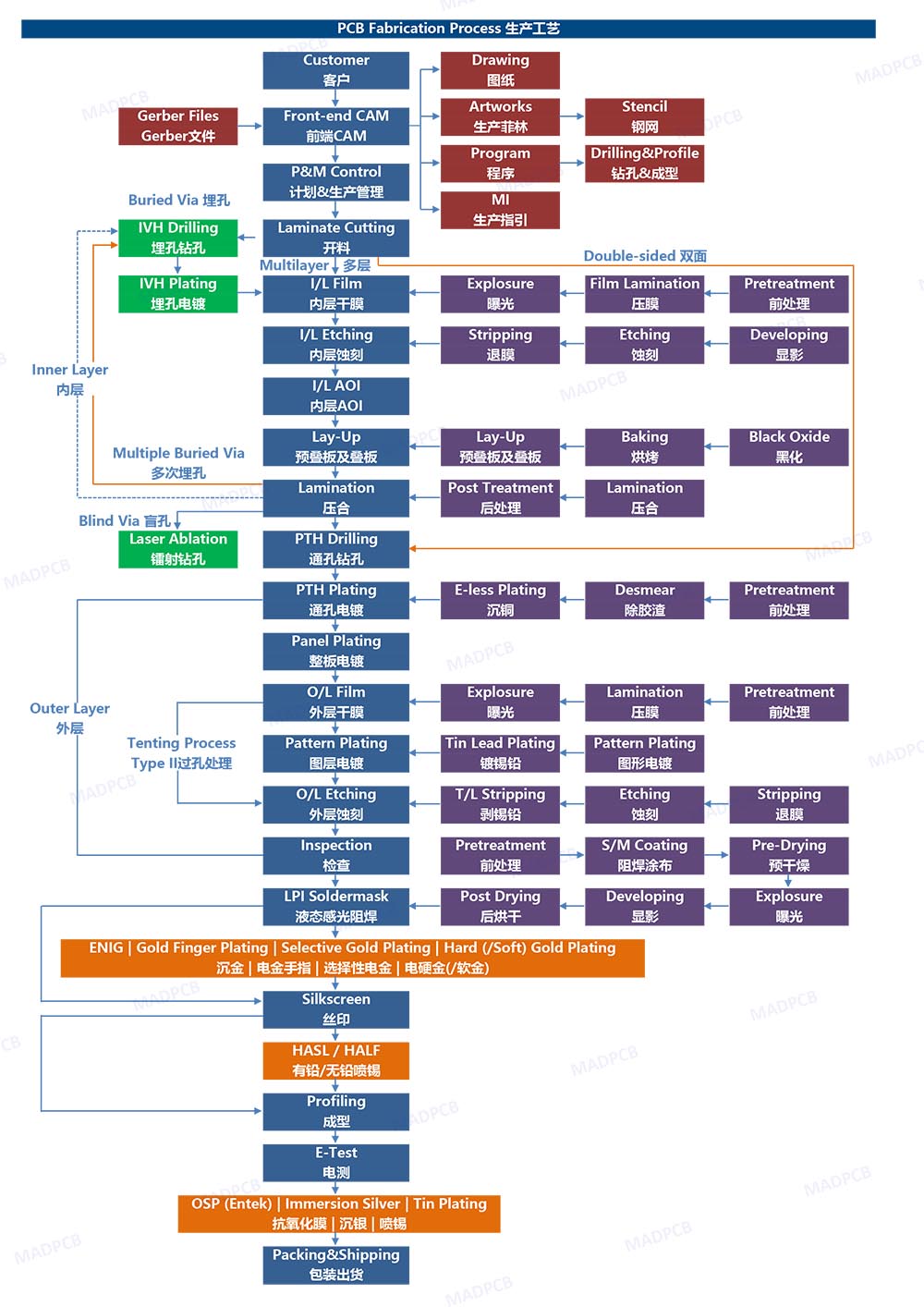

Rigid PCB Fabrication Process

Our rigid PCB fabrication process covers all PCB manufacturing with mechanical thru-holes, mechanical single-to-multiple buried vias, mechanical blind vias, laser ablated blind microvias and depth controlled drilling, supports cutting-edge manufacturing technologies of via-in-pad and thin film embedded passives.

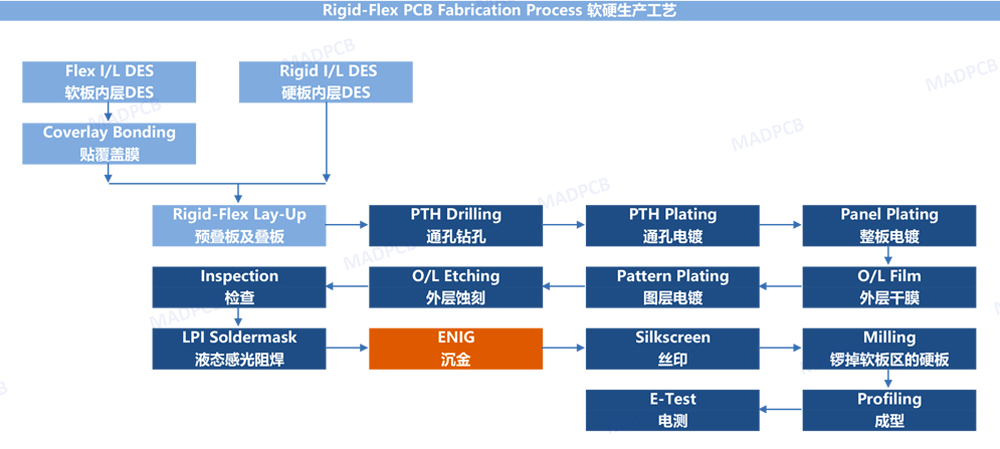

Rigid-Flex PCB Fabrication Process

Our rigid-flex PCB fabrication process covers all kinds of flex circuits and flex-rigid PCB manufacturing. Most processes are the same as rigid PCB manufacturing, and we only briefly introduce you the key manufacturing processes.

For more information about flex circuit and rigid-flex PCB manufacturing process, contact us for answers at any time.

Importance to Understanding of PCB Fabrication Process

When reply to the question “Is it important to understand the PCB fabrication process?”, purchasers may have no interest because they are only responsible for PCB procurement -release orders to the PCB manufacturer, supplier or provider, and receive the PCB boards at the due date. While, electrical and electronic designers may have interest. PCB manufacturing is not a design activity, but when a designer understands the circuit board fabrication process, his design would be more mature and manufacturable with low cost and high quality.

PCB manufacturing process is performed by a printed circuit boards (PCB) manufacturer, all manufacturing activities will accord to the specifications that provided by the outsourcing company, and as per IPC related standards. In most cases, manufacturers are not privy to your PCB design intent or performance objectives, but they will conduct DRC, DFM and DFA checks for you. Therefore, they would not be aware of whether you are making good choices for materials, stack-up, routing, via locations and types, trace widths/spacings or other PCB parameters that design during PCB board fabrication and may impact your PCB’s manufacturability, production yield rate or performance after deployment, as listed below:

- Manufacturability: Whether your PCB is manufacturable depending on a number of design choices, which are including but not limited to keeping adequate spaces between trace and trace, between trace and pad, between pad and pad, between trace and PCB edge, between pad and legend, between trace and drills and etc. as well as annular ring, via structure, via protection type, surface finish, stack-up (thru-hole, buried or blind), slot minimum width, half-hole minimum drilling diameter, material choice (Tg, Dk, Df, CTE, PP, adhesive or adhesiveless PI base for FPC), profile shape, and others. Either of these could result in the inability of your PCB board being fabricated without redesign or re-layout. What’s more, if your PCB is tiny and you decide to panelize it, then you need to confirm with your PCB fabricator whether it’s manufacturable and with maximum material usage rate.

- Production Yield: When your design passes the process of CAM engineering, your PCB seems will be successfully fabricated if following the manufacturing instructions (MI) and other documentations, while fabrication issues may still exist or be in risk of quality. This will reduce the production yield, i.e. quality passing rate. For instance, your fabrication drawings specify tight tolerances that beyond the limits of your PCB manufacturer’s equipment, that will result in higher than acceptable of boards that are unusable.

No matter your board is a prototype or mass production runs, we can come to meet your PCB fabrication needs in a variety of materials and technologies. We focus on multi-layer printed circuit boards, impedance Controlled circuit boards and HDI PCBs in varying complexities.