Table of Contents

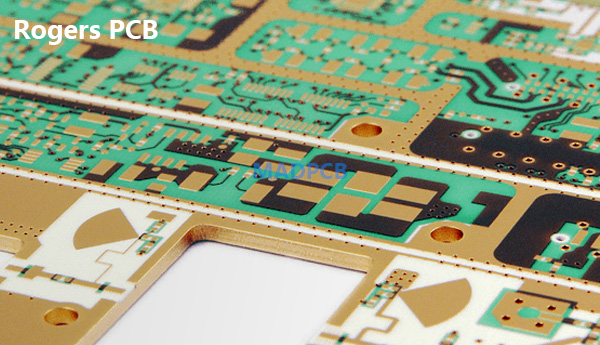

Rogers PCBs

For some PCB designs, dielectric PCB properties are critical when selecting laminates and prepregs (PP). Rogers Corporation has long been industry heavyweight for advanced PCB materials in high frequencies applications. The high frequency Rogers Printed Circuit Boards (PCBs) Manufacturing relies on high frequency laminates that assure improve electrical performance when used in the applications, like

- Antennas

- Antenna Systems

- Carrier-Grade Wi-Fi & LAA Devices

- Communications Systems

- Power Amplifiers

- Telematics and Infotainment

- Active Safety

- Backhaul Radios

- Handheld Device Cellular and Wi-fi Antenna

- Computing

- IP Infrastructure

- Small Cells /DAS

- Test &Measurement

- Phased Array Radar Systems

- Thermal Management

The use of advanced PCB materials not only supports the building of next generation designs but also contributes to lower dielectric loss and low electrical signal loss, among others. As a Rogers PCB Manufacturer, MADPCB has a long-term cooperation with Rogers material suppliers, which supply us high-performance dielectrics, laminates and prepregs from Rogers. With special high frequency circuit materials from Rogers, MADPCB builds Rogers PCBs with high-frequency and high-speed performance. Our range of Rogers PCBs are designed to offer greater thermal performance in severe application environments.

While, there are many restricts when sourcing, some materials are hard to buy. Each procurement should report the information of customer’s company name, address and nationality, product application and purpose, and etc.

Rogers Corporation & High Frequency PCB Materials

Rogers Corporation is headquartered in Chandler, Arizona with manufacturing plants in the United States, China, Germany, Belgium, Hungary and South Korea, its joint ventures and sales offices are located all over the world. The business segment related to High Frequency, or Radio Frequency (RF) Printed Circuit Boards is Advanced Connectivity Solution (ACS).

From 2003, with the foundation of its first facility -Rogers Technologies (Suzhou) Co., Ltd., Rogers starts to process high-frequency PCB copper clad laminate (CCL) materials in China for use in communication applications.

All Rogers PCB Materials for Selection

Rogers’ Advanced Connectivity Solutions (ACS) business provides leading advanced circuit material solutions. ACS manufactures high frequency laminates, bondplys and prepregs, engineered to meet stringent performance requirements. With exceptional dielectric constant control, Rogers’ specialty materials are a consistent and reliable choice for applications including 5G wireless communication, automotive radar sensors, aerospace, satellites and more. ACS Rogers PCB materials include:

- 92ML™ Materials

- AD Series® Laminates

- CLTE Series® Laminates

- CuClad® Series

- DiClad® Series Laminates

- IM Series™ Laminates

- IsoClad® Series Laminates

- Kappa® 438 Laminates

- MAGTREX™ Laminates

- Prepregs and Bondplys

- RO3000® Series

- RO4000® Series

- RT/duroid® Laminates

- TC Series® Laminates

- TMM® Laminates

- XtremeSpeed™ RO1200™ Series

9MLTM Materials

92ML materials are halogen-free, flame retardant, ceramic-filled thermally conductive multi-functional epoxy prepreg and laminate systems. They provide a low-cost, lead-free solder compatible system with enhanced heat transfer characteristics for multilayer PCBs for applications requiring thermal management throughout the entire board volume. 92ML materials are engineered for use with metal backing for producing aluminum metal core PCBs.

Features:

- Thermal conductivity

- 1.6W/m-K in the Z-axis, 10x that of FR4

- 2.3W/m-K in plane

- Decomposition temperature up to 350°C

- Coefficient of thermal expansion in-plane as low as 20 ppm/°C

- Certified to the flammability requirements of UL 94V-0

- Best-in-class thermal performance: T260 > 60minuetes

- Available in the 9MLTM StaCool TM Laminate option -a combination with an aluminum plate to form an insulated metal substrate (IMS).

Benefits:

- Reduces surface temperature, eliminates hot-spots and improves heat sink performance

- Enhances heat transfer by thermal vias

- Provides excellent plated through hole reliability, lead-free solder assembly

- Predictable Registration due to good dimensional stability

- Useful in high power handling applications

- Environmentally friendly composition

- Thermally stable laminate material

AD Series® Laminates

Rogers AD Series PTFE/woven glass based laminates are designed to deliver the consistent, high performance required of high frequency PCB materials for cost sensitive commercial applications.

Benefits:

- Industry leading dielectric constant & thickness tolerance for commercial PTFE materials

- Lower Z-Direction CTE than traditional PTFE woven-glass laminates

- Wide dielectric constant range available: 2.5-10.2

- Loss tangent values ranging from .0014-.003 at 10GHz

- Exceptional product support and product quality

- Broad range of products meet demanding requirements for a variety of designs

CLTE Series® Laminates

Rogers CLTE Series materials offer tight dielectric constant and thickness tolerance, low loss tangent, low out-gassing and low insertion loss. The ceramic, PTFE woven-glass composite material has higher thermal conductivity than conventional PCB dielectrics and is ideal for thin multilayer boards, providing the option of the highest degree of embedded resistor consistency in the industry.

Benefits:

- Improved dimensional stability for tight registration requirements

- Phase stability in applications operating over wide temperature ranges

- Low CTE values ideal for high reliability plated through holes for Avionics, Radars, EW, SIGINT, CNI (Communications, Navigation, Identification) and Phase Sensitive Filters

CuClad® Series Laminates

Rogers CuClad laminates are woven fiberglass reinforced PTFE based composites for use as PCB substrates and radomes in high frequency applications. CuClad laminates feature low dielectric constants (Dk) ranging from 2.17 to 2.60, low electrical loss of tan δ from 0.0009 to 0.0018 at X-band and low moisture absorption. These balanced, cross plied constructed laminates are available up to 36” x 48” in size.

Benefits:

- Stable Dk over wide frequency range

- Suitable for wideband applications

- Provide higher gain in amplifier and antenna designs

- First article success leaders to faster time to market

- Sheet sizes accommodate larger PCB or radome formats

DiClad® Series Laminates

Rogers DiClad Series laminates are fiberglass reinforced PTFE based composites for use as printed circuit board substrates in high frequency applications. The controlled fiberglass and PTFE content ratio enable DiClad laminates to offer a range of low dielectric constant (Dk) values. Higher PTFE content provides a lower Dk and loss tangent, while higher fiberglass content provides better dimensional stability and registration. Unlike the CuClad® laminate series, the DiClad laminates do not have cross plied constructions.

Benefits:

- Stable Dk over frequency

- Suitable for wide-band frequency applications

- Higher gain in amplifier and antenna designs

- Negligible performance drift caused by high moisture environments

- First article success leads to faster time to market

IM Series™ Laminates

Rogers IM Series™ laminates include the IM cladding solution of an ultra-smooth electrodeposited copper foil cladding option which has excellent adhesion to the substrate materials. These laminates consist of a PTFE resin system and are woven glass reinforced for excellent dimensional stability.

Features:

- Low PIM of -166 dBc at .030”

- Dk range of 2.17 to 2.94

- Dissipation factor range of .0009 to .0021 at 10 GHz

- Uniform mechanical properties

- Very smooth copper foil with Rq = 0.5μm by non-contact interferometry method

Benefits:

- Enables successful high performance antenna designs

- Maintains mechanical form during handling

- Greater yield on larger panel sizes

IsoClad® Series Laminates

Rogers IsoClad laminates are non-woven fiberglass reinforced PTFE based composites for use as PCB substrates and radomes in high frequency applications. IsoClad laminates feature low dielectric constants (Dk) ranging from 2.17 to 2.33, low electrical loss of tan δ from 0.0009 to 0.0018 at X-band and low moisture absorption. These balanced, cross plied constructed laminates are available up to 48” x 54” in size.

Benefits:

- Stable Dk over wide frequency range

- Suitable for wideband applications

- Provide higher gain in amplifier and antenna designs

- First article success leaders to faster time to market

- Sheet sizes accommodate larger PCB or radome formats

Kappa® 438 Laminates

Rogers Kappa 438 laminates were designed using a glass reinforced hydrocarbon ceramic system that offers superior high frequency performance and low cost circuit fabrication resulting in a low loss material which can be fabricated using standard epoxy/glass (FR-4) processes. Kappa 438 laminates also have the UL 94 V-0 flame retardant rating and are lead free solder process compatible. Kappa 438 laminates offer dielectric constants (Dk) tailored to FR-4 industry standard norms which facilities ease of converting existing FR-4 designs where better electrical performance is needed.

Features:

- Glass reinforced hydrocarbon thermoset platform

- Dk of 4.38 is tailored to FR-4 industry standard norms

- Tighter Dk and thickness tolerance than FR-4

- Low Z Axis CTE of 42 ppm/°C

- High Tg of > 280°C TMA

- Meets UL 94-V0 requirements

Benefits:

- Ease of PCB manufacturing and assembly in Line with FR-4

- Design Dk enables ease of converting existing FR-4 designs needing better electrical performance

- Consistent circuit performance

- Improved design flexibility and plated through-hole reliability

- Automated assembly compatible

MAGTREX™ 555 High Impedance Laminates

Rogers MAGTREX 555 high impedance laminates are the first commercially available low loss laminate with controlled permeability and permittivity. MAGTREX™ 555 laminates enable antenna designers to expand the trade-space of their antenna design enabling design flexibility and optimization.

MAGTREX 555 materials are constructed from a proprietary, low loss, high resistivity ceramic filler and a high temperature thermoplastic matrix. This yields a system which is conformable, through hole via capable, and mechanically and electrically stable. These laminates feature a closely matched X/Y axis permeability and permittivity of 6 and 6.5, respectively, along with low magnetic and dielectric loss below 500 MHz. MAGTREX 555 high impedance laminates feature a low X, Y, Z CTE closely matched to copper for thermal reliability and are available in thicknesses from 40 to 260 mils. They are offered with or without copper cladding.

Features:

- Matched permeability and permittivity

- High miniaturization factor

- PTFE composite laminate

- Low moisture absorption

- Low dielectric and magnetic loss below 500MHz

Benefits:

- Substrate impedance matched to air

- Antenna miniaturization with improved bandwidth

- Flexible and conformable

- Environmentally stable electrical performance

- High antenna efficiency

Prepregs and Bondplys

Rogers offers a wide arrangement of bonding and adhesion materials directly matched to complement our broad, industry-leading, high frequency circuit material offerings.

Rogers’ portfolio of prepregs and bondplys are designed for consistent reliability and performance for the most demanding multilayer PCB applications. With electrical and mechanical properties exceptionally matched to our high frequency laminates, our wide-range selection of non-reinforced and glass reinforced bonding and adhesion materials provides designers options for a total Rogers solution. Additionally, Rogers’ numerous families of bonding materials are developed on varying technologies, resulting in a range of solutions from the most challenging to traditional process ability methods.

Benefits:

- Thickness range of 0.0015 to 0.005 in.

- Dissipation factor as 0.0009 at 10GHz, at 2.99 Dk

- Available both with and without glass reinforcement

RO3000® Series

Rogers RO3000 high frequency circuit materials are ceramic-filled PTFE composites intended for use in commercial microwave and RF applications. This family of advanced laminates offers exceptional electrical and mechanical stability.

RO3000 Series laminates are circuit materials with consistent mechanical properties, regardless of the dielectric constant (Dk) selected. This allows the designer to develop multilayer board designs that use different dielectric constant materials for individual layers, without encountering war-page or reliability problems. Additionally, the RO3000 series’ dielectric constant is stable over a wide temperature range.

Benefits:

- Lowest loss commercial laminates

- Available in a wide range of Dk (3.0 to 10.2)

- Available both with and without woven glass reinforcements

- Low Z-axis CTE provides plated through-hole reliabilit

RO4000® Series

Rogers RO4000 hydrocarbon ceramic (not PTFE) laminates and prepregs are the industry leader. Used in microwave and millimeter wave frequencies, this low loss material offers easier use in circuit fabrication and streamlined properties over traditional PTFE materials. RO4000 hydrocarbon ceramic laminates are designed to offer superior high frequency performance and low-cost circuit fabrication. The result is a low loss material which can be fabricated using standard epoxy/glass (FR-4) processes offered at competitive prices.

Benefits:

- Compatible with FR-4 fabrication processes

- Well controlled dielectric constants (Dk)

- Above-average thermal conductivity (.6-.8)

- Thermally robust – lead free soldering compatibility

- Low Z-axis CTE for reliable plated through-hole quality

- Optimized cost and RF/ microwave performance

- Wide range of DK available (2.55-6.15)

- UL 94 V-0 flame retardant versions available

RT/duroid® Laminates

Rogers RT/duroid® high frequency circuit materials are filled PTFE (random glass or ceramic) composite laminates for use in high reliability, aerospace and defense applications. The RT/duroid series has a long industry presence of providing high reliability materials with superior performance.

Benefits:

- Low electrical loss

- Low moisture absorption

- Stable dielectric constant over wide frequency range

- Low outgassing for space applications

TC Series® Laminates

Rogers TC Series laminates are PTFE, woven fiberglass and high thermal conductivity ceramic filled materials that provide improved Printed Circuit Board (PCB) thermal management for applications requiring high power RF signals. This improved performance and reliability in high power applications is the result of a low loss tangent, high thermal conductivity, low coefficient of thermal expansion and excellent temperature phase stability.

TC series materials are an excellent choice for applications sensitive to dielectric constant (Dk) changes with temperature, including power amplifiers, filters, couplers and more.

Benefits:

- Reduced junction temperature and improved reliability

- Improved bandwidth utilization and efficiency for amplifiers and antennas

- Reliable for attachment to active components and for plated vias

- Allows for PCB fabricator processing flexibility for optimized panel size

TMM® Laminates

Rogers TMM® thermoset microwave laminates combine low thermal coefficient of dielectric constant (Dk), a copper matched coefficient of thermal expansion and dielectric constant uniformity. Due to their electrical and mechanical stability,

TMM thermoset microwave materials are ceramic thermoset polymer composites designed for high plated thru-hole (PTH) reliability stripline and microstrip applications. TTM laminates are available in a wide range of dielectric constants and claddings.

Benefits:

- Wide range of dielectric constants (Dks)

- Excellent mechanical properties, resists creep and cold flow

- Exceptionally low thermal coefficient of Dk

- Coefficient of thermal expansion matched to copper allowing for high reliability of plated through-holes

- Available copper clad in larger formats, allowing the use of standard PCB subtractive processes

- Resistant to process chemicals, no damage to material during fabrication and assembly processes

- Thermoset resin for reliable wire bonding

- No specialized production techniques required

- TMM 10 and 10i laminates can replace alumina substrates

- RoHS compliant, environment friendly

XtremeSpeed™ RO1200™ Series

Rogers XtremeSpeed RO1200 Series laminates and bondplys are low dielectric constant, low loss materials engineered to meet the unique electrical, thermal and mechanical requirements of high-speed designs. XtremeSpeed RO1200 circuit materials enable system designers the flexibility to design leading edge systems that maximize data throughput and minimize latency in performance demanding applications.

With a low dielectric constant (Dk) and dissipation factor, XtremeSpeed RO1200 materials provide outstanding signal integrity, reduced signal skew and reduced cross-talk. Combined with superior thermal/mechanical performance, low CTE and a halogen free UL 94 V-0 rating, XtremeSpeed RO1200 materials are well suited for the most demanding high layer count applications.

Features:

- Low Dk

- Max dissipation factor of .0017 (Laminate) and .0012 (Bondply) at 10GHz

- Low CTE, Decomposition Temperature (Td) of 500°C TGA

- Low profile rolled copper cladding on laminates

- Spread glass reinforced laminates for improved rigidity and ease of handling

- Unreinforced bondply enables best-in-class electrical performance

- Halogen free

Finding a Rogers PCB manufacturer for quote? Contact MADPCB now!