Table of Contents

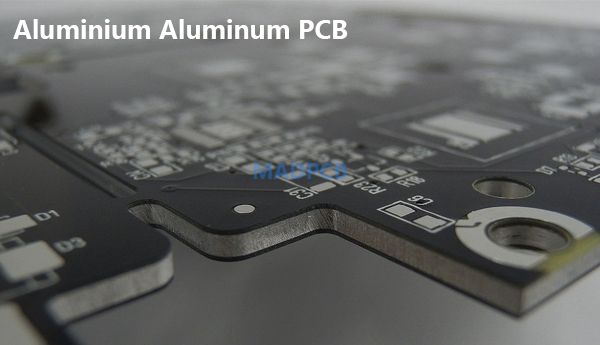

Aluminium | Aluminum Printed Circuit Board (PCB)

Aluminum PCB, or Aluminium PCB, also called Alu PCB, is one of Insulated Metal Substrate (IMS) PCBs, and is also one of the most commonly used Metal Core PCBs (MCPCB) nowadays. MADPCB manufactures Aluminum printed circuit boards (PCB) with a full selection of high-performance substrates, and we work to be the best aluminum PCB manufacturer and provider no matter you need prototypes or high-volume production quantities. Aluminum PCBs typically are single-sided, but also can be double-sided as well. While, multilayer Aluminum PCBs are highly difficult to manufacture.

Aluminum-Based PCB with Copper Layer, Dielectric Layer & Aluminum Layer

Aluminum PCB has a similar layout to any other printed circuit boards with copper layer(s), solder mask layer(s) and silkscreen(s). Instead of having a fiberglass or plastic substrate, Aluminium PCB is made from metal core substrate, which consists of copper layer, dielectric layer and aluminum layer. This substrate is called as Aluminum based copper clad laminate (CCL). The glass reinforced and ceramic filled dielectric layer in-between copper layer and aluminum layer is very thin, but plays a very important role of electric insulation and thermal conductivity (because of minimum thermal resistance) from copper layer to aluminum base. The copper is etched into conductors and metal base is to withdraw thermal (/heat). The superior heat transfer capacity of Aluminum-based PCB helps cooling components while eliminating problems associated with managing fragile ceramics.

Aluminum Based PCB Laminates

We currently support Aluminum based CCLs from Ventec, GDM and BoYu with thermal conductivity from 1.0 ~ 7 W/m·K. The Aluminum PCB prices of Ventec is much higher than that with GDM and BOYU since material cost, and the prices of high thermal conductivity is higher than low thermal conductivity. MADPCB provides a wide range of electrical and thermally conductive interface pads, thermally conductive gap filler, thermal phase change materials and thermally conductive electrically insulating materials, as well as specialized equipment for high volume Aluminium PCB manufacturing. Choosing MADPCB as your Aluminum PCB supplier, just send your Gerber files and fabrication notes to us, we will deliver qualitied PCB boards to you on time.

| Vendor | Part Number | Type | Thermal Conductivity (W/m·K) |

Tg(oC) | Td(oC) | Dk @1MHz | Df @1MHz |

| Ventec | VT-4B1 | Aluminum Base (1100, 5052) | 1.0 | 100 | 380 | 4.8 | 0.016 |

| VT-4B3 | Aluminum Base (1100, 5052) | 3.0 | 130 | 380 | 4.8 | 0.016 | |

| VT-4B5 | Aluminum Base (1100, 5052) | 4.2 | 120 | 380 | 4.8 | 0.016 | |

| VT-4B5 SP | Aluminum Base (1100, 5052) | 5 | 120 | 380 | 4.8 | 0.016 | |

| VT-4B7 SP | Aluminum Base (1100, 5052) | 7 | 100 | 380 | 4.8 | 0.016 | |

| GDM | GL12 | Aluminum Base | 1.0, 1.5, 2.0 | — | — | — | — |

| BOYU | AL-01-B | Aluminum Base | 1.0, 1.5, 2.0 | 120 | — | 4.9 | 0.02 |

Advantages and Applications

Aluminium-based PCBs can consistently increase durability and long-term reliability of a final product through temperature control and associated reductions in failure rates. Aluminum designs also deliver better mechanical stability and lower thermal expansion levels than conventional PCB materials.

- Improved Product Durability

- Increased Power Density

- Increased Thermal Efficiency

- Reduced Number of Interconnects

- Lower Junction Temperatures

- Reduced PCB Size

- Eliminates Older Hardware

- Minimizes Labor Required for Assembly

- Wide Variety of Form Factors

- Minimize Thermal Impedance

Upon above advantages of Aluminum PCB, Aluminium core PCBs are widely used in LED lighting, power conversion, controllers, motor drives, rectifiers, power supply and etc.

Aluminum LED PCB with White Solder Mask

In recent years, the retail prices of Aluminum LED lights have come down significantly, while the energy efficiency and brightness of LED lights have gone up. These improvements in the technology have let to some projections of 45% growth every year for the next five years. With the growth in the LED industry, there has become a higher demand for LED PCBs and solder masks.

Solder mask is a protective coating applied to the bare printed circuit boards. Bare PCB boards are covered with mask to prevent accident solder bridging during PCB assembly and to protect the PCB from the environment. Solder masks are traditionally green color, and are expected to withstand the high temperatures present in reflow soldering for a different color like blue, red, or black arising every once in a while. The rise in LED PCB production has called for improvements in the color white and the color stability of the mask in general. The commonly used LPI solder mask colors in LED PCB are white and black, and the white solder mask is the most used for achieving a high brightness and perfect light reflection. White LED PCB ensures not go dark, and not to affect the color temperature of the LED SMDs. While, it also helps improve the lifespan for the LED light applications.

Finding a reliable Aluminum LED PCB supplier? Count on MADPCB and get a quick quote today.