Table of Contents

Impedance Control in Rigid PCB and Flex Circuits

Electronic components become smaller and PCB designs become faster, in other words, PCB boards are more complicated nowadays. As printed circuit board signal switching speeds increase, PCB designers in this day and age need to understand control the impedance of PCB traces. Short signal transition times and high clock rates of modern digital circuitry requires PCB traces to be considered not as simple connections, but as transmission lines.

At MADPCB, we are capable of calculating and control the impedance of rigid PCBs, flexible circuits and rigid-flex PCBs. As most designers know, the impedance control in FR4 PCBs and PTFE PCBs are easy since the surface are almost absolutely flat, and there are many impedance calculating tools for choice. While, when it comes to flexible and flex-rigid boards, they sometimes feel helpless, that’s may because they haven’t professional impedance field solver tool. For flex PCB, the commonly seen impedance control is Hatch Impedance, or called Cross-Hatching Impedance. The cross-hatching copper layer(s) provides shielding to the impedance-controlled traces, including microstrip and stripline.

What is Impedance?

Impedance is the combination of the capacitance and inductance of a circuit when operated at high frequency and measured in Ohms. The resistance being the opposition to current flow present in all materials. The resistance is the opposition to current flow resulting from the effect of the inherent capacitance and inductance of the conductor interacting with changes in voltage and current. In DC circuits there is no reactance and the resistance of copper conductors is typically insignificant.

What is Controlled Impedance PCB?

Controlled impedance PCBs are the printed circuit boards with controlled impedance in the stages of design, manufacturing and performance. It’s hard to control impedance, unless you carefully design the PCB’s trace and its work environment because impedance will vary in value from point to point along the trace. At high frequencies, PCB traces do not behave like simple circuit connections, controlled impedance helps us ensure that signals are not degraded as they route around a printed circuit board.

Controlled impedance is the matching of PCB base material properties with trace dimensions and locations to ensure the impedance of a trace’s signal is within a certain percentage of a specific value. Controlled impedance PCBs provide repeatable high frequency performance.

What Determines Controlled Impedance?

The characteristic impedance of a PCB trace is typically determined by its inductive and capacitive reactance, resistance, and conductance. These factors are a function of the physical dimensions of the trace, the DK (or Er, dielectric constant) of the PCB substrate material at certain frequency, and dielectric thickness. PCB trace impedance can range from 25 to 125 ohms. The impedance value generated from the PCB structure will be determined by the following factors:

In Rigid PCBs:

- Signal trace’s width/spacing and thickness

- Dielectric core and/or prepreg thickness

- Dk (/Er) value of the core and prepreg

- Distance from other copper features

- Dk (/Er) value of the solder mask

In Flex Circuits:

- Hatch Width (HW) and Hatch Pitch (HP)

- Polyimide (PI) thickness of the FCCL

- Signal trace’s width/spacing and thickness

- Thickness of Adhesive in-tween FCCLs

- Dk (/Er) value of Polyimide (PI)

- Dk (/Er) value of Coverlay

- Dk (/Er) value of Adhesive

When to Use Controlled Impedance?

Controlled impedance should be considered and used when a signal must have a particular impedance at high frequencies to function properly. In high frequency products, it is important to matching the impedance of PCB traces to maintain data integrity and signal clarity. If the impedance does not match the components’ characteristic impedance, the switching time may be increased, and the circuit may meet random errors.

Common Controlled Impedance Types

Single-Ended Impedance

Single-ended impedance is one of the commonly used impedance types in printed circuit board (PCB), which is the impedance on a certain length of a trace. The CAM engineer in your PCB supplier will firstly calculate the controlled impedance to decide how much traces modification and how to adjust the matching of materials and the board’s stack-up, then the planner arranges the impedance-controlled PCB fabrication. The impedance controlled single-ended impedance can be measured on a single trace, which is not coupled to the adjacent line. From the Coated Microstrip type interfaces of Polar SI9000, the single-ended impedance is affected by PCB board substrate height, substrate dielectric Er value, trace’s lower and upper width, trace thickness (/copper weight), coating (/solder mask) thicknesses and coating dielectric. The main factors to decide the single-ended impedance are dielectric Er value and trace width. And other factors are insignificantly affected to the impedance calculation result.

Differential Impedance

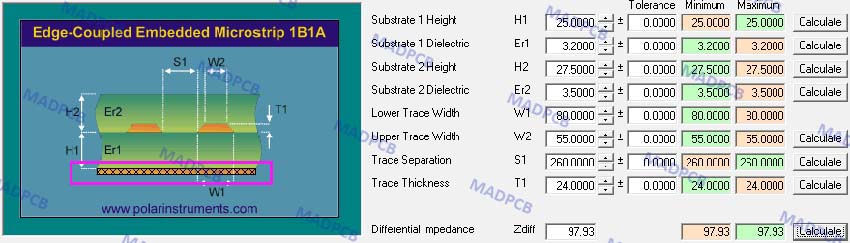

Differential Impedance is another commonly used impedance types in circuit board design and manufacturing. Differential impedance is the impedance between a pair of traces, also known as differential pair traces, when driven by equal and opposite polarity signals. From the Edge-Coupled Coated Microstrip type interfaces of Polar SI9000, we know the differential impedance is affected by many factors, including PCB substrate height, dielectric Er value, trace widths, trace separation (/spacing), trace thickness (/copper thickness), coating (/solder mask) thicknesses and coating dielectric. When handling differential impedance calculation, the main factors to decide the impedance is substrate height, Er value, trace width and spacing.

Both Single-ended Impedance and Differential Impedance can be applied into the hatching impedance of flex PCBs and rigid-flex PCBs.

How to Ensure the Controlled Impedance?

As a controlled impedance PCB manufacturer, we use Polar SI9000e impedance calculation software and impedance tester to meet controlled impedance requirements. Before PCB production, our engineer simulates all impedance values upon given information in the calculation software. Once all impedance matched, we put the controlled impedance PCB into production. When PCB manufacturing completed, we measure the impedance results of the impedance test coupon with the impedance tester. If all impedance values are within acceptable tolerance +/-5% or +/-10%, the controlled impedance is success.

Controlled Impedance Printed Circuit Board (PCB), also called as Impedance Controlled PCB. As a leading PCB manufacturer and supplier China, MADPCB provides customers prototypes and high-volume PCB boards with a variety of fabrication notes.