Table of Contents

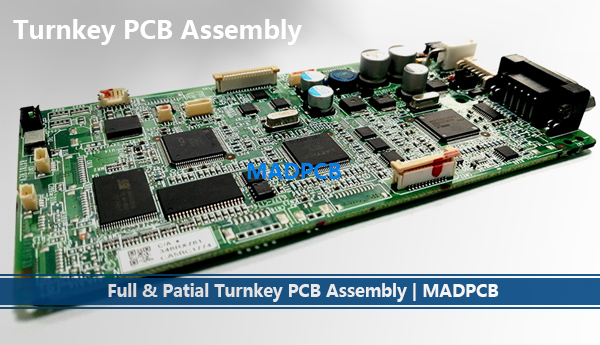

Full and Partial Turnkey PCB Assembly Services

As a professional contract turnkey PCB assembly manufacturer with extensive experience in PCB fabrication, parts sourcing, design and assembly for electronics outsourcing companies or individuals. Our specialty ranges from prototype to high-volume assembly on basis of full turnkey PCB assembly and partial turnkey PCB assembly. The minimum order quantity (MOQ) can be 5pcs. For last 10+ years, we have been globally serving customers with high quality PCB board assemblies and reliable, industry-leading contract manufacturing services from China.

Full Turnkey PCB Assembly Service

Full turnkey PCB assembly requires customers to send their design files, whereas the contract manufacturer will provide SMT stencil, PCB boards, and the parts required on BOM for the assembly. This means everything right from parts procurement to assembly is performed by the PCB assembly manufacturer. The following are the key benefits of availing this PCB assembly service.

- Most manufacturers have strong relationships with parts suppliers, which helps them source the parts effectively at competitive prices.

- The parts are mostly procured in assembly friendly packages, like cut-tapes, or tape and reels to save cost.

- A customer can be relaxed that all procurement and assembly is being handled by the manufacturer.

Partial Turnkey PCB Assembly Service

As the name implies, in this type of PCB assembly, a customer sources some components and parts, and the rest is sourced by the manufacturer. In this process, the manufacturer has to seek approval from the customer on parts’ prices, their quality, and availability, before the actual assembly starts. Partial turnkey PCB assembly is favored by many OEMs owing to the following reasons:

- This type of assembly helps strike a good balance between kitted and turnkey.

- A customer provides expensive parts such as connectors, IC’s and etc., whereas the PCB assembler will source the rest parts, which helps saving time for both sides.

- If a customer has built strong supply chain relationships then they can easily benefit in terms of prices by sourcing parts at cheaper rates.

- Assembly process and preparations will be much faster than the full turnkey assembly.

With our PCB and assembly manufacturing facilities in Shenzhen, MADPCB serves customers in a variety of industries, including Industrial, Communications, Medical, Wearable Devices, IoT, Navigation System, Bio-robotics, Monitoring System, Aviation, LED Lighting and etc., due to our commitment to meet the customers’ specifications, quality, cost considerations and on-time delivery. Every PCB assembly is manufactured in compliance to standards of ISO 9001, RoHS, IPC-A-600 and IPC-A-610, which also ensures the product -PCBs and PCBAs are finished in our SMT house meet environmental and regulatory requirements.

PCB Assembly Types MADPCB Can Handle

- Rigid Board, MCPCB, Flexible and Rigid-Flex PCB assembly

- Single- and Double-sided Assembly

- Lead-free (RoHS) PCB assembly

Quick Review of MADPCB Assembly Services

- Printed Circuit Board Assembly

- Full/-Partial Turnkey Assembly

- Quick-turn Assembly with Partial Turnkey Service

- Components Sourcing

- Electronics & Microelectronics Assembly

- PCB and PCBA Prototypes

- SMT Assembly

- Thru-hole circuit board assembly

- Hybrid assembly

- Strategic supply chain management

- Wiring & Cabling

- Box build

- Final assembly

- IC programing

- Visual inspection & Electrical testing

- 0.3mm pitch BGA assembly

- Flex PCB stiffener assembly

- Lead-free and RoHS compliant assembly

PCB Board Assembly Quality Control

- All bare PCB boards are assembled to comply with IPC-A-610 standards.

- All assembling technicians and inspectors are with skilled experience.

- All PCB manufacturing handles by ourselves to comply with IPC Class II or III standards upon requirements.

- 100% electrical test on all bare Printed Circuit Boards by flying probe or fixture.

- 100% visual inspection after electronic PCB assembly completion.

- 100% functional test as per documented test procedures (optional).

- 100% all PCBAs cleaning.

- Strict electronic static discharge (ESD) control.

Files Requirement

- Gerber or ODB++ Files: please include all the layers (copper, solder mask, silkscreen, solder paste, outline, thru-via hole, blind and buried via, micro-via, carbon ink printing, FPC stiffener, EMI film and etc.).

- Bill of Materials (BOM) in Excel format. Your BOM should include:

- Reference designators (required)

- Quantity per board (required)

- Manufacturer part number (required)

- Manufacturer (optional)

- Description (optional)

- Type (SMD, Thru-Hole, Fine-Pitch, BGA, etc.) (optional)

- Package (QFN32, SOIC, SOT23-5, 0402, etc.) (optional)

- It is highly desirable to include columns to indicate whether the parts are consigned by you, MADPCB supplied or not populated.

- Centroid File: also known as pick and place file, or coordinates file. It should include component locations, rotations and reference designators in .csv format.

- Assembly Drawings (Optional) if there are solder paste layer in your Gerber file zip folder.

- Assembly Notes, useful for complex PCB and assembly manufacturing, usually in .pdf format. (Optional)

With advanced assembly equipment and years’ experience, our daily SMT capability reaches 1.5 million points, and our PCB assembly lines are versatile for rigid PCB Assembly, Flex PCB Assembly and Rigid-flex PCB Assembly with FR-4, Rogers, Metal Core, Ceramic and Polyimide (PI) materials.