Table of Contents

Rigid-Flex PCB

Nowadays, rigid-flex printed circuit boards (PCBs) are used in many applications, like drones, computers, wearable electronics, medical device and testing equipment. MADPCB is a famous thru-hole and high density interconnect (HDI) rigid-flex PCB manufacturer in Shenzhen, China.

What Is Rigid-Flex PCB?

A rigid-flex PCB is composed of a combination of rigid boards and flexible circuits that are permanently laminated and interconnected to one another through vias. Rigid-Flex also written as Flex-Rigid. Rigid-flex PCBs go across the boundaries of traditional rigid PCBs and the unique properties of flexible circuits that use high-ductility ED or RA copper photo-etched onto a flexible insulating film.

Flex circuits include stack-ups made from a flexible Kapton polyimide and copper laminated together through heat, adhesive and pressure. Rigid flex circuits provide higher component density and better quality control. As with conventional boards, you can mount components on both sides of the rigid-flex circuit board.

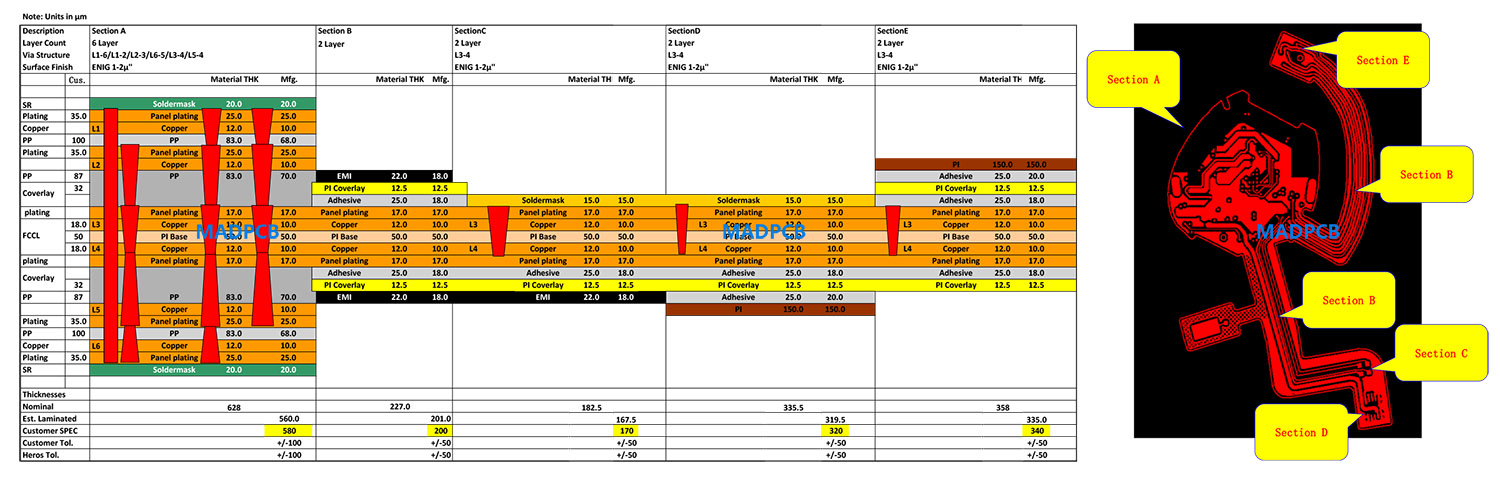

Every rigid-flex PCB board is divided into zones that feature different materials and varying layer counts. Rigid zones may have more layers than flexible zones, and materials shift from FR-4 to polyimide in transition zones. Complex designs often transition from rigid to flex and back to rigid multiple times. As these intersections occur, the overlap of rigid-flex materials requires keeping holes away from the transition zone to maintain integrity. In addition, many rigid-flex designs include stainless steel or aluminum stiffener(s) that provide additional support for connectors and components.

Advantages of Rigid-Flex Boards

- Accommodate controlled impedance

- Elimination of additional components such as ZIF connectors and connecting cables

- Improves the ability of the circuit to transmit signals without loss.

- Weight reduction

- More valuable component assembly and wiring space

- Reduced logistical complexity

- Solution of difficult contacts is possible, simplification of assembly

- Considerably improved reliability of the entire PCB system

- Combination with HDI PCB mircovia technologies (microvia, buried and blind vias, finest conductor lines) is possible

- Combination with heatsink technology is possible

- Remarkable improvement of functional testability

Contract your project to MADPCB, the professional rigid-flex PCB manufacturer, will benefits more than expectations. Here is a 6-layer any layer interconnect (ALIC) rigid-flex board manufactured by us.

Rigid-Flex PCB Challenges

Different challenges offset the versatility and flexibility that allow you to build rigid-flex PCB designs and products. Traditional rigid-flex circuit board designs allow you to mount components, connectors, and the chassis for your product to the physically stronger rigid part of the assembly. Again, in terms of traditional designs, the flexible circuit only served as an interconnect while lowering the mass and improving the resistance to vibration.

New product designs coupled with improved flex circuit technologies have introduced new design rules for rigid-flex boards. Your design team now has the freedom to place components on the flexible circuit area. Combining this freedom with a multilayer approach to rigid-flex printed board design allows you to build more circuitry into the design. However, gaining this freedom adds a few challenges in terms of routing and holes.

What Are Rigid-Flex PCB Design Rules?

- Flexible circuits always have bend lines that affect routing. Because of the potential for material stress, you cannot place components or vias close to the bend line.

- And even when components are properly located, bending flex circuits places repeated mechanical stresses on surface-mount pads and through holes. Your team can reduce those stresses by using through-hole plating and by bolstering pad support with additional coverlay to anchor the pads.

- As you design your trace routing, follow practices that reduce stress on your circuits. Use hatched polygons to maintain flexibility when carrying a power or ground plane on your flex circuit. You should use curved traces rather than 90° or 45° angles and use teardrop patterns to change trace widths.

- These practices decrease stress points and weak spots. Another best practice distributes stress across traces by staggering the top and bottom traces for double-sided flex circuits. Offsetting the traces prevents the traces from laying over each other in the same direction and strengthens the PCB.

- You should also route traces perpendicular to the bend line to reduce stress. When moving from rigid to flex and back to rigid, the number of layers from one medium to the other may differ. You can use trace routing to add stiffness to the flex circuit by offsetting the routing for adjacent layers.

What Are Rigid-Flex PCB Materials?

Rigid-flex PCBs are the vital mechatronic components used in a lot of applications. The range of materials used to in the rigid-flex PCB fabrication is as diverse as its application area. There are numerous materials available for rigid-flex PCB assembly. However, the selection must be made after careful analysis of the board’s application and thickness requirements. Besides, the area of application, MADPCB suggests several other factors need to be considered when making the material selection such as:

- Reliability requirements

- Duration or shelf life of the application

- Manufacturing methods

- Cost and budget

Commonly Used Materials in the rigid-flex PCB Manufacturing

The most commonly used rigid-flex PCB materials are:

- Substrate Materials -The basic material used for rigid-flex PCB manufacturing is woven fiberglass, which is thoroughly impregnated with epoxy resin. However, epoxy imprinted fiberglass is not always a reliable solution as it fails to resist frequent vibrations, shocks, and constant (Er or DK) movement. Hence, for applications in demanding environments, rigid-flex printed circuit boards are manufactured using:

- Polyimide (PI): Polyimide is largely preferred over epoxy resins due to its versatility, toughness, and resistance to constant movements of elevated and fluctuating temperatures.

- Polyester (PET): Polyester is usually available in 25-125μm (1-5mil) thickness, this substrate material is chosen for its excellent flexibility and electrical properties. But nowadays, PET is rarely used in FPC manufacturing.

- Conductor Material: Copper is the most commonly used and readily available conductor material for rigid-flex circuit assembly. The material is preferred due to its benefits such as high workability and good electrical characteristics. For circuitry applications, two forms of copper foils are typically used – electro-deposited (ED) and rolled annealed (RA) cooper foil. Both these foil forms are available in various thickness and weights. They are subjected to surface treatment before they are used for the rigid-flex PCB assembly. Sometimes, constantan foil is adopted for constantan FPC fabrication. The foils are chemically treated to reduce bond degradation, increase adhesion, augment bond strength, and protect from oxidation.

- Bonding Sheet: Bonding sheet (also called Adhesive) plays an important role in extending the service life of rigid-flex boards. They are responsible for making secure connection between the substrate and conductor materials. Deciding on the type of adhesives and the required thickness to bond substrate and conductor is the most crucial part in rigid-flex circuit board manufacturing.

- PP: Prepreg is used to bond FR-4 CCL, copper foils in rigid parts. In complex board design, MADPCB rigid-flex PCB manufacturer prefers to use low-flow prepregs in the fabrication to ensure high quality.

Rigid-Flex PCB Surface: Coverlay vs. Solder Mask

The surface of rigid-flex PCBs is comprehensively coated using protective films, which is called protective coating. This helps rigid-flex PCB resisting chemicals, oils, hydrocarbon solutions, dust, and other contaminations. The protective coating is selected after understanding the types of materials used in the rigid-flex PCB assembly, compatibility of PCB components with the coating material, and most importantly the application areas. The most commonly used forms of coating are:

- Coverlay: When a flexible film like polyester or polyimide is combined with a suitable adhesive, the resulting product is a cover layer (coverlay). Coverlay has three major roles to play in a rigid-flex PCB assembly: (1) to provide comprehensive protection to the entire assembly. (2) to access circuitry areas like circuit pads for further processing. (3) to augment the reliability and resilience of the circuitry.

- Solder Mask: Unlike coverlay method, a thin coating of liquid acrylated epoxy and acrylated polyurethane solder mask ink is applied onto the circuitry surface. The liquid coating is applied using several methods, one of such is screen printing. The coating is then thermally cured. In some complex rigid-flex boards, the coverlay openings on flex parts are so dense, we suggest to use flexible solder mask.

Besides these materials, there are several other optional materials used in the fabrication of rigid-flex boards to augment their operational excellence and reliability. These include anti-tarnishing coatings, and back pressure sensitive adhesive (PSA). As a reliable Rigid-flex PCB manufacturer and provider, MADPCB chooses these materials as per the needs of customers, and specific application requirements.

The material used greatly determines the quality and overall functioning of the rigid-flex boards. As mentioned earlier, PCB materials must be carefully chosen after analyzing several criterial including cost, shelf life, and electrical requirements of the printed circuit board, among others. This helps produce rigid-flex PCBs that provide many years of reliable and trouble-free service.

IPC Standards for Rigid and Flexible PCBs

The list of IPC standards below applies to rigid PCBs and flex circuits. Take note that this list is not exhaustive, and additional IPC standards may need to be considered. You should consult the ipc.org website for a full list of available IPC standards.

- IPC-2221A, Generic Standard on Printed Board Design

- IPC-2223, Sectional Design Standard for Flexible Printed Boards

- IPC-4101, Specification for Base Materials for Rigid and Multilayer Printed Boards

- IPC-4202, Flexible Base Dielectrics for Use in Flexible Printed Circuitry

- IPC-4203, Adhesive Coated Dielectric Films for Use as Cover Sheets for Flexible Printed Circuitry and Flexible Adhesive Bonding Films

- IPC-4204, Flexible Metal-Clad Dielectrics for Use in Fabrication of Flexible Printed Circuitry

- IPC-6013, Qualification and Performance Specification for Flexible Printed Wiring

Find a Rigid-flex PCB manufacturer in China? You can count on MADPCB, which supports rigid-flex PCB prototypes and mass production. For meeting quick-turn PCB requirement nowadays, our professionals can offer quickly after receipt of your inquiry. What’s more, we can attach the stack-up proposal and panelization in the offer no matter it’s simple or complex rigid-flex boards. This makes us different from most rigid-flex PCB manufacturers and trading companies.