Table of Contents

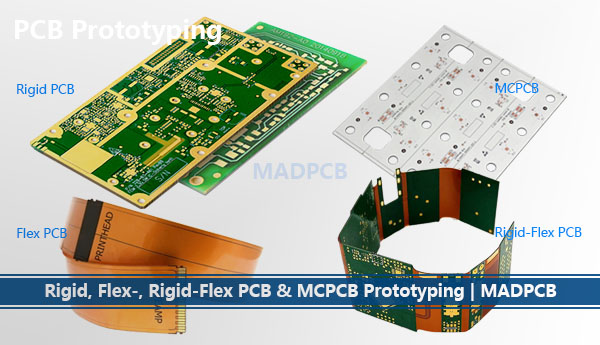

PCB Prototyping Services

Printed circuit board (PCB) Prototyping allows engineers to check whether the design will perform as their expectations. At the same time, your PCB prototyping manufacturer would like to check if your circuit boards can be manufactured efficiently. Multiple prototyping runs can be used to test the PCB design variations or to perfect a single function before moving on to the afterwards PCB production stage.

PCB Prototyping Stages

During PCB prototyping, many engineers focus on design experimentation to get proof of concept, this stage PCB prototyping makes it little more possible to prove that your design concept will actually work in electronic product. It’s far more cost-effective to test variables at this point than to produce high volume PCBs with a defect design. If the 1st stage PCB prototype proves to work, engineers may adjust and optimize the design considering PCB manufacturing complexity, PCB cost, component cost, mechanics, assembly complexity, and some others in mind. Then it comes to the 2nd stage PCB prototyping, the final product is coming much closer to reality with this prototype. When this prototype assembly works as the expectations, the design goes to be the final version, although some changes might still need to make before production. Before production, your prototyping may need one time, two times, or three times, which ensures the circuit board works perfectly in high volume production. Finding a reliable and quality priority PCB prototyping supplier is important for the early launching of your product in the market without quality risks. PCB Prototyping | Printed Circuit Board manufacturer | Mad PCB

Can We Skip Prototyping Process?

Some engineers and purchasers might think it’s easier and quicker to skip the PCB prototyping process. That might be true if everything works exactly as your designed functions, but does that every actually happen? The answer is definitely no. Prototyping service provides a great way to ensure the PCB production has no problem in manufacturing, assembly and functioning.

Benefits of Circuit Board Prototyping

Prototyping benefits listed below help you make the right call for your PCB manufacturing goals. A good PCB prototyping service provider and prototype manufacturer offering a prototype service will have a dedicated team and section to carry out your project and will ensure quality and results as per your needs.

- Superior Quality: Professional PCB manufacturers specializing in prototype have expertise in relevant industry knowledge. They are abreast with latest technical developments, regulations and market trends so it would be much easier for them to help you with product development with their insights. By availing service from a prototype PCB Manufacturing service your product development process will become stronger from the use of their advanced CNC machinery, superior quality materials, and their expertise when making your prototypes.

- Testing Assistance: Another good reason to work with a prototype PCB manufacturing service provider is that they will be able to detect and improve technical and human errors as per your project needs. The service provider will take care of design red flags in a timely manner for you to be able move ahead with the product design. This is crucial because the final has to withstand many unfavorable but unavoidable conditions like temperature changes, shocks and power fluctuations.

- Faster Turnaround Time: Adhering to timelines can be difficult when you have outsourced multiple service providers. The follow-ups can also be very frustrating. If you want efficient and quicker completion, then only a one-stop specialist company will be able to help you. Working with an expert PCB prototyping service will make it easier for you to follow a streamlined process. A dedicated prototyping PCB service will understand and accommodate to time-sensitive requirements of your project. Contact a rapid PCB prototyping service provider to complete your project in just a few days.

- Best Design Assurance: Less time to complete the project does not have to mean that the end product will be of a substandard quality. A good prototype PCB manufacturing service provider will never let you settle with a mediocre product for the market. They will make sure that they do your design and product aspiration with their service. Seek professional assistance from a fast PCB prototype service to help your company with quality design.

- Cost Effective: Exceeding overhead costs can be a cause of concern not just for new companies with limited budgets but also established companies. Choosing a rapid prototyping service can help you manage your resources efficiently by not having to spend on surprise overhead costs. If a company opts to manufacture prototypes on its own they will have to spend incredibly large amounts of money for equipment set up, material and trained labor.

- Seamless Process: Having various providers work on your project can do more harm than good. There are chances of lapse in communications and many differing opinions can actually prove to be roadblocks which will not only hinder you from completing your project in a timely manner but also may result in you having to settle for a lesser-quality than you had originally planned. Having a one-stop solution provider will alleviate such concerns and help you move ahead with a seamless process.

- Time Saving: When you outsource a PCB prototyping company, you are able to focus on other projects. Their efficient team will ensure that your project completes in a timely manner without any errors. That will free up your time and you will be able to focus on other aspects of your business such as marketing, research and development etc.

- Customization: Prototypes are most likely to change before its final completion. Not only does their size get modified but in many cases the components are changed as well, in some cases the whole shape might change. It is important to note that not every manufacturer offers customization options, make sure you choose a PCB service provider that has the tools and facility to help you achieve your product goals.

- Latest Trends & Technologies: A PCB prototyping service provider with ground experience will know what the market trends and so they will be well-equipped to help you with the other aspects of your project such as design and packaging of the product. It is important to note that other processes like design of the product, packaging, etc. depends on the design and size of PCB which can be confirmed only with the prototype.

- Realistic execution: Accurate idea of how your design idea will pan out thereby giving you an idea about you’re the end product will fare in the market with regards to unique proposition if any and the overall practicality. Look for top PCB manufacturing service provider to successfully realize your design and product goals.

From the closest relationship between design and reality, looking for a PCB manufacturer which is able to fabricate your board in prototyping and mass production really matters. The manufacturer should offer PCB prototyping service as part of an all-in-one manufacturing experience. This way your board supplier will best understand how to quote, answer your design concerns, and so on. Yes, MADPCB is a such supplier you can count on for PCB prototyping, production, components sourcing, assembly, functional testing (FCT) and PCB design. We can help you to perform DRC (design rule checks), Design for Manufacturability (DFM), Assembly (DFA) and Testability (DFT), and all these works are for delivering you reliable and well-functioning printed circuit boards in prototypes and mass production.