What Is Td in PCB?

Td (Decomposition Temperature) is the temperature at which a PCB material chemically decomposes (the material loses at least 5% of mass weight), which is determined as per IPC-TM-650 Method 2.4.24.6. Like Tg, Td is expressed in units of degrees Celsius (℃). This parameter determines the thermal survivability of the material.

Td Test Methods Manual

IPC-TM-650 Decomposition Temperature (Td) of Laminate Material Using TGA is the test method, which establishes a procedure for determining the thermal deposition (Td) of base laminate materials using thermogravimetric analysis (TGA). Use of this test method for printed circuit boards (PCBs) or other composite may not yield comparative results.

In this test method, firstly we need to prepare test samples. The sample may be an unclad laminate material or laminate material (CCL) with copper completely removed and that has been cut (using water cooling/cleaning only, no oil) approximately square to fit into the TGA sample pan. Typically, sample mass (weight) is 10mg to 30mg. Samples shall be cut to the specified size using appropriate procedures and equipment to minimize mechanical stress and/or thermal shock. Samples of the same mass but with a smaller surface area may lose mass at a slower rate.

All edges of the samples shall be finished smooth and burr-free by sanding or equivalent (to allow the sample to rest completely flat on the sample pan). Use care to minimize the introduction of mechanical stress or heat to the sample. The accuracy of the mass measurements shall be within +/-0.01mg.

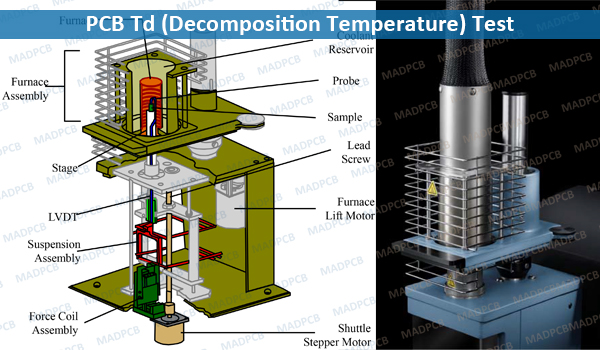

Thermogravimetric Analysis (TGA) instrument shall comprise the following:

- Microbalance, null type, sensitive to 0.001mg

- Furnace equipped with dry (dew point below -68℃ [-90℉], moisture less than 3.5ppm nitrogen (less than 20ppm oxygen) purge.

- Temperature programmer capable of providing controlled 10℃+/-0.1℃ [18℉+/-0.18℉] per minute heating rate from ambient to 800℃ [1472℉]

- The TGA shall be capable of measuring mass to within 0.01mg of actual value

Test Procedure

- The test samples should be baked at 110℃+/-2℃ [230.0℉+/-3.6℉] for 24 hours and placed in a desiccator for cooling to room temperatures (equilibration) prior to testing. In standard lab conditions, the TGA test should be started within 15 minutes of removing test sample from the dessicator because samples may gain mass due to moisture absorption.

- Calibrate the balance to within +/-0.01mg.

- Calibrate the temperature sensor to within +/-1.0℃ [1.8℉].

- Set the purge rate of 55cc/min (0.9mL/s). Run the TGA gas purge for 30 minutes before inserting a sample. The rate of flow of the gas in the cell will have a significant effect on the calibration, therefore, the instrument must be calibrated with the same flow rate as is used during the test. The temperature sensor should be positioned so that it does not come into contact with the same flow rate as is used during the test. The temperature sensor should be positioned so that it does not come into contact with sample at any time. After the temperature sensor has been correctly positioned, the instrument can be calibrated. Neither the sensor position nor the flow rate should be subsequently changed.

- Place the sample in the TGA and measure its mass.

- Heat the sample at a rate of 10℃/min from ambient (not to exceed 50℃) to 550℃.

- Record the temperature, Td (2%), at which the mass of the sample is 2.0% less than it mass measured at 50℃.

- Record the temperature, Td (5%), at which the mass of the sample is 5.0% less than its mass measured at 50℃.

- Report the information: (a) the initial mass of the sample; (b) the room temperature and relative humidity under which testing was conducted; (c) the thermal decomposition temperature, Td (2%); and (d) the thermal decomposition temperature, Td (5%).

How to Choose the Td of a PCB Base Material?

A PCB laminate material’s Td is an important ceiling when assembling PCBs, because when a material reaches or surpasses its Td, changes to its properties are not reversible. Contrast this to Tg, where properties will return to their original states once the material cools below the Tg range.

When exposed to temperatures past a certain threshold, a PCB substrate will decompose. In the process, the PCB loses 5% or more of its overall mass. The temperature range in which this process occurs is known as decomposition temperature (Td). Choose a PCB base material where you can work in a temperature range that’s higher than Tg but well below Td. Most solder temperatures during PCB assembly are in the 200 ℃ to 250 ℃ range, so make sure Td is higher than this. While, it’s lucky that most materials have a Td greater than 320℃. But before choose a material, please consult with your sales representative at MADPCB.