Table of Contents

What’s Teardrop in PCB?

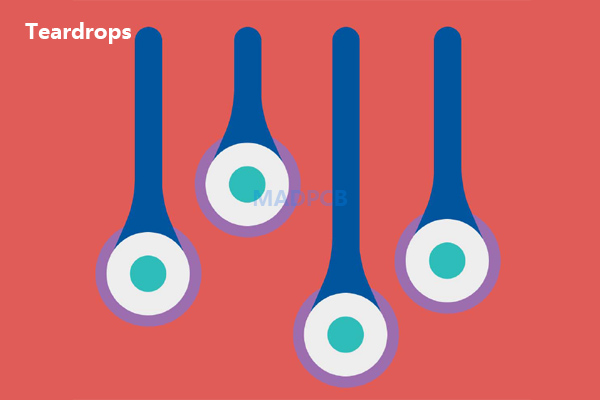

In printed circuit board (PCB) manufacturing, we always meet teardrop or tear drop. What’s teardrop? Teardrops or tear drops are typically drop-shaped features at the junction of vias (teardrop vias) or contact pads (teardrop pads) and traces (teardrop traces).

Why Add Teardrops?

- Teardrop enhances PCB structural integrity in presence of thermal or mechanical stresses where the trace joints the pad resulting in less hairline cracks in traces.

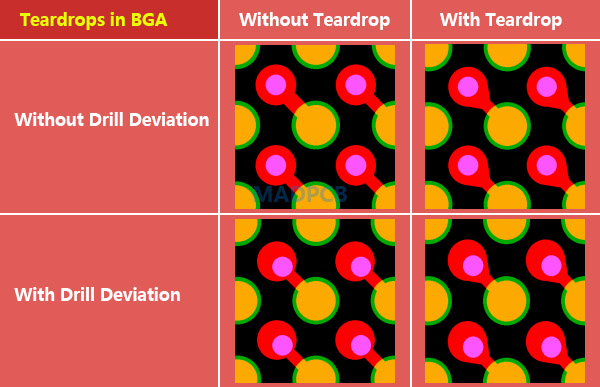

- Teardrop enlarges the PCB tolerance of the drill to pad and could reduce the PCB cost of complex boards.

- Teardrop can reduce risk of PCB cracking and improve yield.

- Teardrop improves resistance to thermal shock mostly effecting rework and wave soldering during PCB assembly.

- Teardrop improves resistance to thermal shock of the product if found in rush environment.

- Teardrop improves resistance to impact shearing.

Where to Add Teardrops?

- Add teardrops for thru-holes where the trace to pad ratio is small.

- Add teardrops for high density boards where the annular ring around vias should be kept.

- Add teardrops on flex boards to reduce the stress where the trace joins the pad.

- Add teardrops under BGA where have lots of vias.

- Add teardrops when traces exist the pad whether it is a solid pad or a pad with a via.

- Add teardrops when the trace become narrow.

- No need to add teardrops when conductor more than 20mil.

How and When to Add Teardrops?

- It is always better, and MADPCB recommends to ask the PCB layout engineer to do the teardrops.

- This way you get the same result with any PCB manufacturer how will product your PCB board.

- In some cases, this feature is simply a check box on your CAD system or something that your PCB designer will do for you -you just have to ask.

- In RF or high frequency boards, it is important to have full control of your PCB layout. Teardrops should be added at the design stage itself.

- The PCB fabricator has teardrop creation engine. When auto teardrop creation is allowed to the PCB manufacturer, teardrops connections can be made so DFM routes will be kept.

- In any case we recommend you design with tear drops or give acceptance to PCB manufacturer to add tear drops in working Gerber making stage.

- In some cases, a teardrop cannot be added, most PCB layout software “know” when to add and when it not possible to add teardrop, not need worry about that.

Signal Integrity and Teardrops

Information under this section are not confirmed by consensus:

- A teardrop shape pad typically only recommended for frequency above 1GHz.

- The extra capacitance of the teardrop shape balances the effect of the inductance associated with a via.

What Type of Teardrop to Add?

While a typical shape of a teardrop is straight-line tapering, they may be concave. This type of teardrop is also called filleting or straight. To produce a snowman-shaped teardrop, a secondary pad of smaller size is added at the junction overlapping with the primary pad (hence the nickname).

- One way (called “snowman”) is to add secondary pads at the junction of an existing pad and the trace, the secondary pad is smaller than the primary pads, and the center is placed few mils away from the center of the primary pad.

- The other more common way is called Filleting or Straight, several traces are added from the existing pad towards the existing trace.