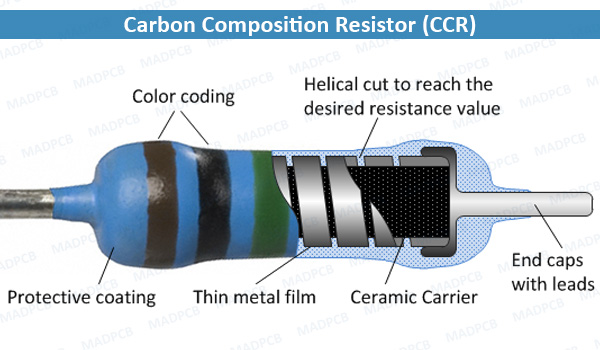

The carbon composition resistor is a two-terminal carbon type resistor that opposes or reduces or restricts the excess current flowing through the electrical and electronic circuits. These are used as general-purpose resistors. These are fixed resistors. These types of resistors are most widely used in the earlier 1960s. These are less expensive, and smaller in size. These can withstand over high energy pulses generated in the circuit. But these days, these types of resistors are rarely used due to the high cost, poor stability, noise, high sensitivity, and smaller power dissipation capacity.

Carbon composition resistors (CCRs) were commonly used in the 1960s and earlier, but are not popular for general use now as other types have better specifications, such as tolerance, voltage dependence, and stress. CCRs are still available, but relatively expensive.

There two types of color coding. They are general coding and precision coding.

General Coding

It includes 4 color coding with a tolerance of greater than ±5%. The numeric values are represented by the first two color bands, while 3rd is for multiplier and 4th is for tolerance. These types of coding are used in general-purpose resistors.

Precision Coding

To evaluate the resistance of the carbon composition resistor, precision coding includes 5 color bands with tolerance <±2%. The first three bands represent numerical values, fourth is for multiplier and fifth is for tolerance.