What Is A Cut-Tape?

Cut-Tape or Cut Tape is a strip of components cut off from a full tape and reel. While tape and reel is long, continuous, and wound up in a reel, and can be cut into a few or many cut-tapes. For projects of prototype PCB assembly and short run PCB assembly, procuring components in cut tape packages will save BOM cost since full reels may contain thousands of components and cost more.

How Many Components You Should Source for A Cut-Tape?

A cut-tape can meet the requirement of just ordering the exact quantity you need. Component suppliers will cut the exact quantity needed a full reel tape into customized quantities to fulfill your order. But if the quantity per board of a 0402 capacitor is 5pcs/board, and the PCB assembly quantity you want is also 5pcs, how many exact such capacitor quantity you should source? Is it 5×5=25pcs? Absolutely Not! For more information, please check our Parts Overage section in the page of Assembly Reminders.

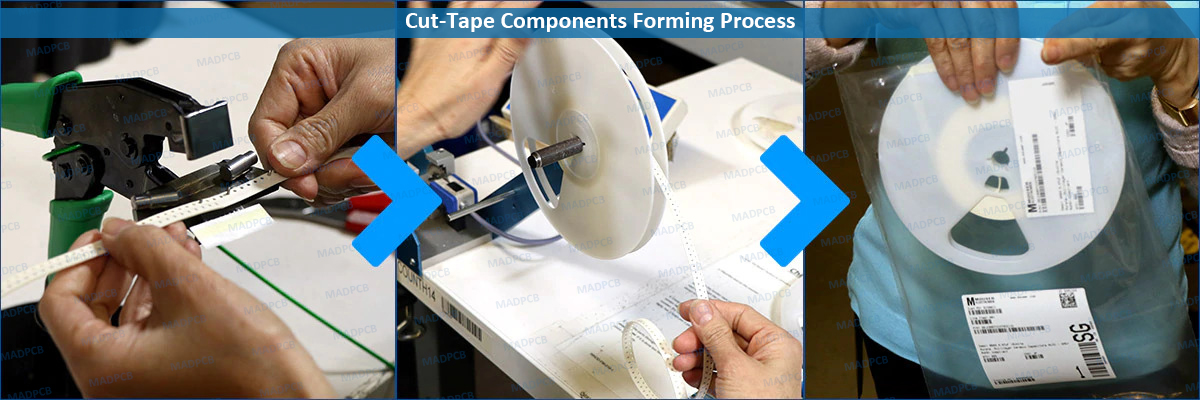

How Does A PCB Assembler Handle Cut-Tape Components?

- Mounting into feeders: Cut-tape components sourcing can save your money, but consider what happens when you provide cut tapes to your PCB assembler. For each cut tape, the assembler needs to mount it on a feeder, so parts can be automatically fed into machine for placement. Each feeder needs a couple of feet of blank leader tape, attached with special tape to your piece of cut tape. The first 3 or 4 components worth of cut tape will need to be peeled back to attach the leader tape. Those 3-4 components need to be repocketed at a later time in the cut-tape, which leads to extra manual handling and can be a source of error and lost parts.

- Dealing with misfeeds: If you also supply only the exact number of parts required for your circuit boards, the PCB assembler may need to spend extra time dealing with misfeeds, or possibly not do a complete run for you due to dropped components. If you do choose to use cut tape, supply at least 5 or more additional components upon part packages, to allow efficient handling. If you don’t know how many should be provided? just contact us for details.

- Cost Calculation: Let’s look at some costs associated with an example run. Suppose you have 20 pieces of cut-tape for your job. For each tape, there is USD1 of joiner tape needed, plus about 10 minutes of extra time per tape of component. At average engineer rates of USD50 per hour this added about USD200 to your job. If you are only doing 20 boards, that’s USD10 per board. Figures will differ for different manufacturers, and some machines may be better or worse at handling cut tape, but as a rough estimate, assume that your job costs USD10 more per cut tape and that you will fail to get a complete run unless you supply extra components.

- Single or multiple pieces of cut-tape of each part? A further thing to be aware of is that there is no guarantee that you will get a single piece of cut tape for each part when you buy your components as cut tape. You may end up with several pieces, and each of these needs to be mounted separately. The extra pieces of cut tape will either stop production as they need to be mounted when the previous pieces have been consumed, or they will take up extra feeder slots. The number of components lost in production is proportional to the number of pieces of cut tape for the part. Since it is known that components provided as cut tape can be in multiple pieces of tape, assemblers will either have to assume the worst when they give you a quote, wait until they see the components before giving a quote, or just give an estimate before the job.