Inductors

Inductors are an electronic component that store electrical energy in a magnetic field when electrical current passes through. They are made using an insulated wire wound into a coil. When electricity flows into this coil from left-to-right direction, a magnetic field is generated in the clockwise direction. Hence, inductors oppose any change in current passing through them.

Usually, there are three types of inductors seen in the market:

- Air core inductors

- Iron core inductors

- Ferrite-core inductors

The air core and iron core inductors carry low inductance, minimal frequency operations, and higher losses. However, ferrite core inductors have a fixed value, high permeability, and high inductance. Therefore, ferrite core inductors are popular and considered a better way out to avoid this problem.

In this article, we’re going to share with you some important information about ferrite core inductors, their characteristics, and their applications.

What is a Ferrite-Core Inductor?

A Ferrite-Core Inductor is a inductor manufactured with a ferrite core inside its coil. When these solid metal cores are used in inductors, the changing magnetic field exhibits large eddy currents because of the electrical conductivity of the metal. These currents circulate within the inductors alongside the closed-loop of electric current.

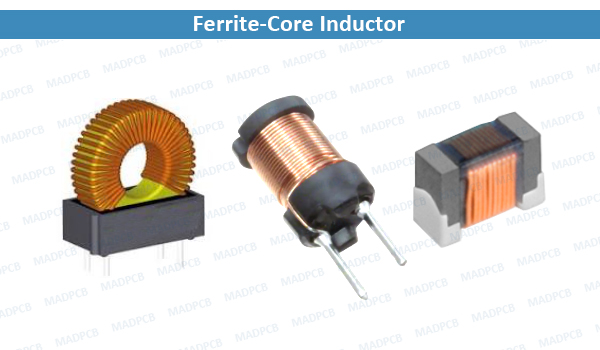

Ferrite-Core Inductor

Ferrite core inductors are used in a range of electric circuit applications including power conversion, broadband, and interference suppression.

While using ferrite cores in inductors, we consider the following things:

- High saturation

- High impedance

- Fewer losses

- Stability in temperature

- Properties of the material

Why Use Ferrite-Core Inductor?

Using Ferrite cores in inductors helps to improve the performance of the inductors by providing high permeability to the coil. It leads to an increase in their magnetic field and inductance. Usually, the permeability level in the ferrite core inductors ranges between 1400 to 15,000, depending on the type of ferrite material used. Thus, ferrite core inductors boast of high inductance as compared to other inductors with air core.

Also, inductors are a major type of passive linear circuit element besides capacitors and resistors. They contribute in producing electronic circuits of superior quality. So, we prefer to use them over others.

Losses

Electronic engineers prefer to use ferrite core inductors because of the losses they exhibit and their dependence on frequency levels. The eddy current losses in the inductors increases exponentially while the hysteresis loss increases linearly with the increase in frequency and flux.

Out of the two core losses, the hysteresis loss is the dominant one but up to a frequency level that depends on the performance of the cores, beyond which eddy current loss predominates.

Characteristics

- In ferrite core inductors, the current passes to generate a magnetic field and the change in magnetic field results in the passing of an opposing current.

- They change electrical energy into magnetic energy and store the energy in them.

- They allow DC (Direct Current) but not AC (Alternating Current) to pass through them at higher frequencies.

- High Quality Factor – Material with low core losses; gapped ferrite core structure

- Performance over temperature – Closely controlled µi (initial permeability) versus temperature

- Minimum Stray Field – Use of toroid or pot core

- High inductance – Attained by using ferrite materials with high permeability

Applications

- Ferrite Core inductors can be used in coils that are operated between a frequency range from AF to 100 MHZ

- They can be used in power transformers that operate in a low frequency range between 1 to 200 kHz

- They can be used at both medium and high frequencies

- They can be used in switching circuits

- They can be used in Pi Filters

- They can also be used in the ferrite rod antenna designed for medium wave receivers

- Telecommunications is the largest and most critical segment apart from communications, entertainment, controls and other industries

- Common mode inductors in power conditioning or power supply components

- Prevention of common mode noise generated by the equipment from escaping into circuitry

With these, you can always ensure high permeability, high inductance, and low eddy current losses for a variety of high-frequency applications.