What Is Heavy Copper in PCB?

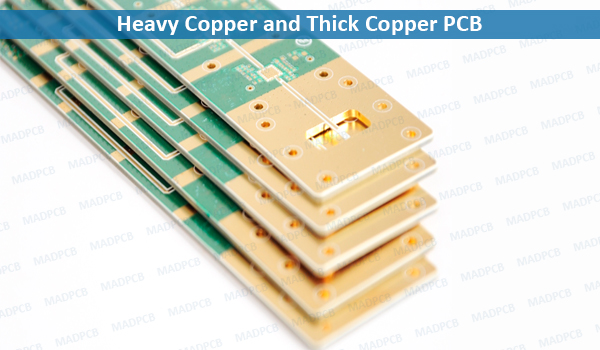

The IPC has no any specific definition of Heavy Copper (Cu) in PCB, but people in PCB industry generally define it as the copper weight of outer and/inner conductive layers equals or higher than 3oz.

For example, when the finished copper weights of a 4-layer PCB is 3/2/2/3oz, we call this board as Heavy Copper PCB. Heavy Copper PCBs can be rigid boards, flexible printed circuits (FPCs), and rigid-flex boards.

What Is Copper Weight in PCB?

The Copper Weight of PCB materials (like CCL, FCCL and copper foil) and in finished boards is originally defined as the weight of copper on a certain area, specifically, refers to 1oz (28.35g) of copper is pressed flat and spread evenly over a one square feet area, with unit oz/ft2 (oz = ounce, and ft = feet), or simply oz.

No matter how to press (refers to RA copper) or electro deposit (refers to ED copper), the processed copper has a thickness. That’s why today Copper Thickness is more commonly to define the copper weight. We can easily convert copper weight to copper thickness as 1oz = 1.37mil (0.00137inch) = 34.798μm (0.034798mm).

As with all things that are manufactured there is manufacturing tolerance that we must take into consideration. The IPC-4562 standard allows for up to a maximum of 10% reduction in the base copper thickness as supplied by the base material manufacturer. Besides, Table 3-13 IPC-6012 states the min final copper thickness after processing as following:

When the copper thickness in PCB equals or more than 3oz = 4.11mil (or 4.2mil)= 105μm, the heavy copper PCB is also called as Thick Copper PCB, or Thick Cu PCB.MADPCB is capable of manufacturing both double-sided and multilayer PCBs with traces and copper planes of up to 6oz with both plating and non-plating techniques. Our main advantage is in building at a reasonable cost heavy copper PCBs. Our engineering team can work with you to review your design to make sure that they can be manufactured with the highest quality at the best overall cost.

|

Table 3-13 IPC-6012: Internal Layer Foil Thickness after Processing |

|||

|

Imperial |

Industry Defined Copper Thickness |

Initial Copper Thickness |

Min Final Copper Thickness |

|

3/8 oz |

12 µm | 12 µm | 9.3 µm |

| 1/2 oz | 18 μm | 18 μm |

11.4 μm |

|

1 oz |

35 µm | 35 µm | 24.9 µm |

| 2 oz | 70 µm | 70 µm |

70 µm |

|

3 oz |

105 µm | 105 µm | 55.7 µm |

| 4 oz | 140 µm | 140 µm |

86.6 µm |

For more info about PCB copper thicknesses, you can refer to following contents: