What Is Laser Ablation?

Laser Ablation (LA) or Photoablation is the process of removing material from a solid surface by irradiating it with a laser beam. At low laser flux, the material is heated by the absorbed laser energy and evaporates or sublimates. At high laser flux, the material is typically converted to a plasma. Usually, laser ablation refers to removing material with a pulsed laser, but it is possible to ablate material with a continuous wave laser beam if the laser intensity is high enough. Excimer lasers of deep ultra-violet light are mainly used in photoablation.

See our term Laser Drilling and page HDI PCB.

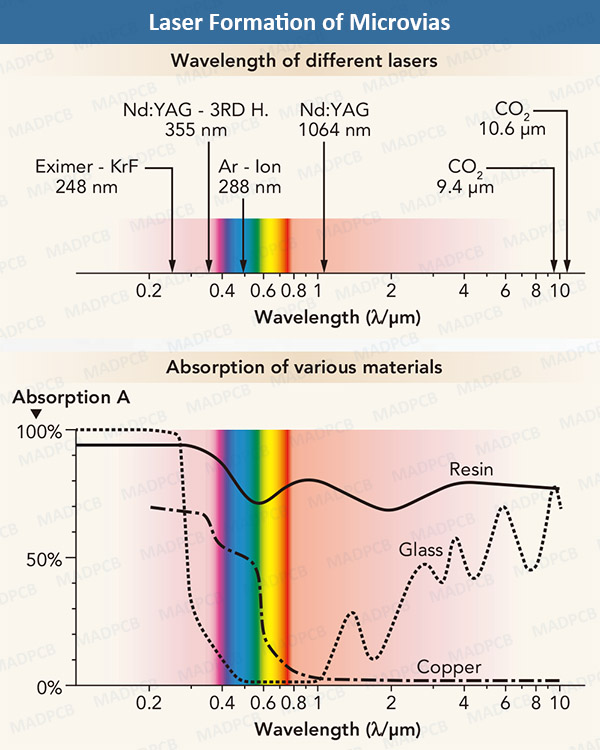

Laser ablation is a complex process. The laser penetrates to the sample surface, depending on the wavelength of the laser and the refractive index of the target material. The high electric field generated due to laser light is enough to remove electrons from the bulk sample. The generated free electron collides with the atoms of the bulk sample, in which transfer of energy occurs. This leads to the heating of the surface, which is followed by vaporization. When the laser flux is high enough, the material will transfer to the plasma state, including atoms, molecules, ions, clusters. The pressure difference between the seed plasma and the atmosphere leads to a rapid expansion and cooling of the plasma. LA takes place in either a vacuum or gaseous environment. LA combined with a tube furnace is called a pulsed Laser ablation technique. This technique allows better control over growth temperature, flowing gas type rate, and pressure. LA refers to the process of removing a certain portion of a material from the surface by high-intensity laser treatment. It is widely used in many industrial settings, such as laser machining and drilling, as it allows a controllable amount of energy in duration and dosage to be applied to the specific target area.

In printed circuit board (PCB) manufacturing, laser ablation technique is always used to drill microvias, sometimes drill high-density small vias (>=0.2mm), cut flexible materials and flex- and rigid-flex boards’ depth control.