- Protect specific areas on the PCB during the reflow soldering, wave soldering, or surface finish process.

- For DNI (Do Not Install) or Not Populated parts, printing peelable mask on the pads or PTHs prior to PCB assembly to prevent an accumulation of excess solder on the empty pads.

- It is also necessary for parts that will be manually installed after automated PCB Assembly is complete.

- Selective gold surface finish (both soft gold and hard gold PCB) also require such mask to ensure that the correct finish is only applied to the desired areas of the PCB.

- This solder mask can also protect carbon elements and gold plated contacts during high volume PCB assembly.

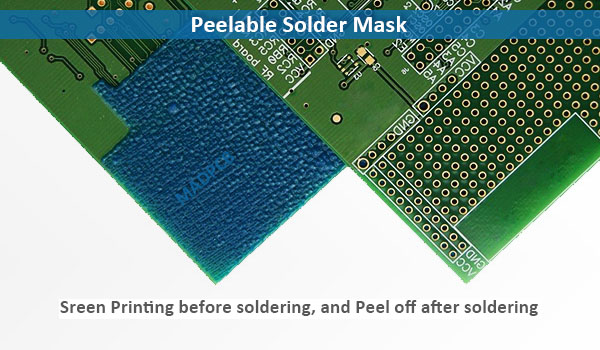

Compared with the manual application of heat-resistant masking tapes, peelable solder masks offer significant technical and economic advantages. They are a considerably less time- and cost-consuming application than adhesive tapes, for example, and there are no difficult-to-remove adhesive residues. They also offer automatable and reproducible register-true application by screen printing, and even difficult areas, such as gold-plated rotary contacts, can be covered and protected without any problems. Depending on the ink type they are also suitable for multiple soldering, reflow soldering and lead-free soldering.

When manufacturing printed circuit boards (PCBs) and assemblies, it is often necessary to cover certain areas prior to soldering operations in order to avoid them being wetted with solder. Such areas may be gold contacts, gold-plated rotary contacts multipoint connectors, Carbon conductive touch-key contacts or even larger areas for which selective soldering and multiple soldering is necessary (e.g. mixing PCB assembly).

This covering can either be carried out but with heat-resistant tape or by using peelable solder masks which are usually applied by screen printing to offer a very simple yet cost-competitive coverage compared to tapes. However, the field of application and requirements has grown enormously, with the latest challenge being compatibility with Lead-free soldering process and their increased processing temperatures.

After soldering, the masks are peeled off manually.