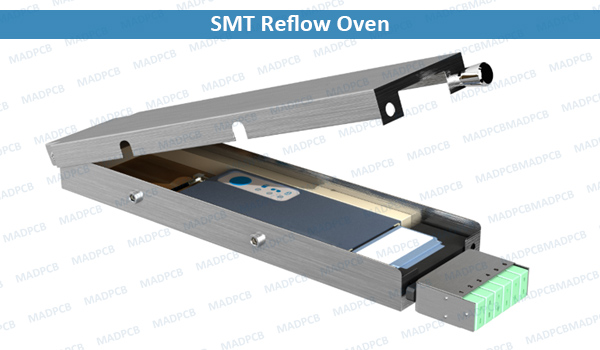

What Is A SMT Reflow Oven?

A Reflow Oven is an electronic heating machine used to mount electronic components to printed circuit boards (PCBs) through surface mount technology (SMT) in PCB assembly process. The thermal processing of solder for electronics manufacturing takes place in a reflow oven.

In the early days of electronics PCB assembly, infrared (IR) heating technology was employed. Later on, the industry switched to convection heat transfer. There are two types of reflow ovens as following:

- Infrared and Convection Ovens: The oven contains multiple zones, which can be individually controlled for temperature. Generally, there are several heating zones followed by one or more cooling zones. The PCB moves through the oven on a conveyor belt, and is therefore subjected to a controlled time-temperature profile. The heat source is normally from ceramic infrared heaters, which transfers the heat to the assemblies by means of radiation. Ovens which also use fans to force heated air towards the assemblies are called infrared convection ovens. Some ovens are designed to reflow PCBs in an oxygen-free atmosphere. Nitrogen (N2) is a common gas used for this purpose. This minimizes oxidation of the surfaces to be soldered. The nitrogen reflow oven takes a few minutes to reduce Oxygen concentration to acceptable levels within the chamber. Thus, nitrogen ovens typically have nitrogen injection in at all times which decreases defect rates.

- Vapor Phase Oven: Also known as Condensation Soldering. The heating of the PCBs is sourced by thermal energy emitted by the phase transition of a heat transfer liquid (e. g. PFPE) condensing on the PCBs. The liquid used is chosen with a desired boiling point in mind to suit the solder alloy to be reflowed. Some advantages of vapor phase soldering are:

- High energy efficiency due to the high heat transfer coefficient of vapor phase media

- Soldering is oxygen-free. There is no need for any protective gas (e.g. nitrogen)

- No overheating of assemblies. The maximum temperature assemblies can reach is limited by the boiling point of the medium.

Configurations of Inline Reflow Ovens

Inline Reflow Ovens are configured with a number of heating zones followed by cooling section(s). Depending on the length and throughput of the oven there may be few zones, 8 or less, or many zones, 12 or more. During the SMT reflow process, the zones are programmed with a thermal set point. This set point corresponds to the temperature the circuit board should be exposed to as it passes through that zone. The set-up of temperatures for all of the zones and the belt speed is referred to as SMT Program. The temperature that the board passes as it is processed through the oven is called Profile.

Thermal profiling is the act of measuring several points on a circuit board with a thermal profiler to determine the thermal excursion it takes through the soldering process. In the electronics manufacturing industry, SPC (statistical process control) helps determine if the process is in control, measured against the reflow parameters defined by the soldering technologies and component requirements.

How Solder Reflow Oven Works?

For ensuring soldering SMDs to a circuit board, the heat should be transferred to the solder alloy past until its temperature reaches to its molten point. The liquid alloy will merge with PCB copper pads and become a eutectic alloy mixture. A solder joint will be formed after it cools down below molten point.

There are three ways to transfer heat from heat source to heated objects as following:

- Conduction: Thermal conduction directly transmits through a substance when there is a difference of temperature between adjoining regions, without movement of the material. It occurs when two objects at different temperatures are in contact with one another other. Heat flows from the warmer to the cooler object until they are both at the same temperature.

- Radiation: Heat transfer through radiation takes place in form of electromagnetic waves mainly in the infrared region. Radiation is a method of heat transfer that does not rely upon any contact between the heat source and the heated object. The limitation of radiation is that black body will absorb more heat than white alloy.

- Convection: Heat convection is the transfer of heat from one place to another by the movement of fluids, such as air or vapor gas. It is also a contactless method to transfer heat as well.

Advanced solder reflow oven uses the concepts of radiation and convection combined. Heat is emitted by ceramic heat element with infrared radiation, but it doesn’t deliver it to a PCB directly. The heat will transfer to a heat regulator first to make heat output even. A convection fan will blow the hot air to an inner chamber. The target PCB can will get heat consistency in any spot. Get quick quote before submitting your prototype or high-volume PCB assembly projects done in the SMT house of MADPCB now.