Route and Retain, also called Tab-Route, or Tab-Routing, is a term of PCB panelization, in which more than one board of either the same or different design into a given array (or panel). This is a popular PCB panelizing method that uses tabs with or without perforations (or mouse bites). After the panelized boards go through PCB assembly process, the single boards then can be separated by breaking or cutting the tabs that are between the boards, or between the boards and rails in the array.

With tab-routing panelized PCB array, it allows to get multiple circuit boards manufactured and assembled at the same time. This results in lower costs for the project and faster completion of the PCB order. If you will separate the panelized PCBs manually, you should use the perforated type. If you think breaking the PCB off the assembly array would cause too much stress on the PCB, it is wise to use a special depaneling tool – depaneling carrier (with a router machine) that will prevent board damage.

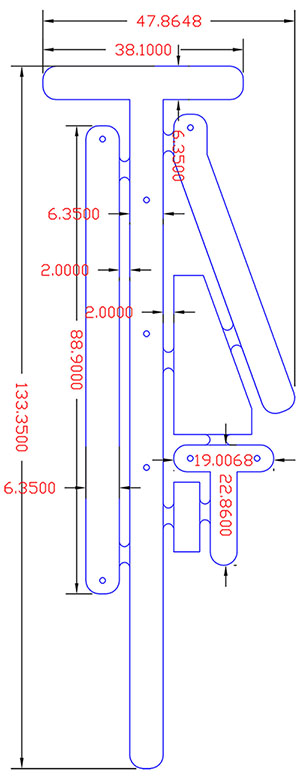

Tab Routing Defaults

If without panelization notes from customers, a tab-routed panelized array will use the parameters stated below for set up by our CAM engineers. Check to know details about our route and retain panelization.

- Place and locate the tabs at least 9mm from all board corners.

- Locate tabs at least 9mm from the datum holes or directly on center.

- A 2mm router should be used. The preferred spacing between boards should be at least 2mm.

- Ensure the tabs are placed in a straight line with an X – Y axis when possible.

- To avoid breaking traces or holes, do not tab the part holes or traces that are near the board edge.

- The width of the tab is 3mm+/-0.25mm.

- The dimension of the tab location tolerance is +/-0.5mm.

- Tabs should be dimensioned to the center on a 0.5mm grid.

- Locate tabs at least +/-6mm from any radius on the outside board edge.

Click to read more about our PCB Panelization Guidelines