What Is a Schematic Diagram in PCB?

A Schematic Diagram is defined as a simple two-dimensional circuit design showing the functionality and connectivity between different components. Sometimes, we call it simply as Schematic, or PCB Schematic.

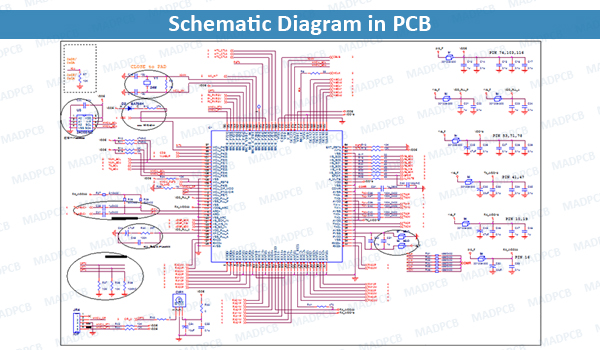

Schematic Diagram in PCB

On the other hand, PCB designs are three-dimensional layouts that indicate those components’ locations once you know your circuit works. The PCB schematic, then, is the first part of designing a printed circuit board (PCB). It is a pictorial representation, either written or on a computer, that utilizes agreed-upon symbols to describe circuit connections. It also indicates the components that will be used and how they are connected. Anyone should be able to pick up and read the schematic diagram.

Its name aptly describes it: the PCB schematic is a plan, a blueprint. Its concern is not where specifically the components will be located. Instead, the schematic lays out how the PCB will ultimately achieve connectivity and forms a critical part of the planning process.

Once the blueprint has been completed, the PCB design comes next. The design is the layout, or physical representation of the PCB schematic and includes the copper track and hole layout. The PCB design does show the locations of the components mentioned above, as well as their connections with copper.

PCB design is the phase that’s concerned with performance. Engineers build the real components on top of the PCB design, allowing them to test whether the device works or not. We mentioned before that anyone should be able to understand a PCB schematic, but the functionality is not readily understood by looking at the PCB prototype.

Once both of these phases have been completed and you’re satisfied with the performance of your PCB, the printed circuit board (PCB) manufacturer can help you bring your device to life.

PCB Schematic Diagram Elements

Now that you have a broad overview of the differences between the PCB schematic and PCB design, let’s take a close look at the elements of PCB schematics. As we mentioned, all the connections are visible, but there are some things to keep in mind.

- To be able to see the connections clearly, they are not created to scale; on the PCB design, they may be quite close to one another.

- Some connections might cross one another, which can’t happen on the physical version.

- Some connections might be on opposing sides of the layout with markings indicating that they are linked.

- This PCB “blueprint” may be represented on one page, two pages, or even several pages – as many as it takes to fully depict everything that needs to be included in the design.

Once final thing to note is that more complicated schematics may be grouped by function to aid readability. Arranging connections in this manner is something that doesn’t happen in the next stage, and schematics often don’t match up to the final design on the 3D model.

PCB Design Elements

Now it’s time to take a more in-depth look at PCB designs elements. At this stage, we move from written blueprints to a physical representation that is constructed using laminate or ceramic material. Some more complicated applications require the use of flexible PCB when exceptionally tight space is a concern.

The elements of PCB designs follow the blueprint that the schematics process has laid out, but, as we’ve mentioned, look very distinct visually. We’ve already talked about what the PCB schematics diagram look like, but what differences can we observe in the PCB design?

When we talk about PCB designs, we’re talking about a 3D model that includes the printed circuit board and the design files. They can be single or multiple layers, though they are most commonly two layers. We can observe several differences between PCB schematics and PCB design:

- All components will be the right size and in the correct position.

- If two connections shouldn’t be connected, they must avoid crossing one another on the same level either by taking a detour or changing to another PCB layer.

Additionally, as we touched on briefly, the PCB design is more concerned with performance, as this is somewhat of a testing phase for the final product. At this point, the practicalities of how the design must actually work come into play, and the physical requirements of a printed circuit board much take them into consideration. Some of these things include:

- How components are spaced to allow for adequate heat distribution

- Having connectors on the edges

- How thick the various traces must be with regard to current and heat concerns

Because physical constrains and requirements mean that the PCB design generally looks quite different than what is mapped on the schematics, the design includes a silkscreen layer. This silkscreen layer indicates letters, numbers, and symbols that help engineers assemble PCB and use the PCB board.

Once you have assembled all the components on the printed circuit board, it works as you’ve planned. If not, it’s back to the drawing board.