TO Package family consists of many types of packaging solutions for transistors and similar discrete devices as well as simple ICs with low pin counts. The structures of TO packages vary widely, from expensive metal can enclosures to low-cost plastic-molded bodies.

JEDEC standards for transistor package begin “TO” (transistor outline); other standards sometimes use “SOT” (small-outline transistor) for surface mount devices (SMDs). If possible, please use the JEDEC name.

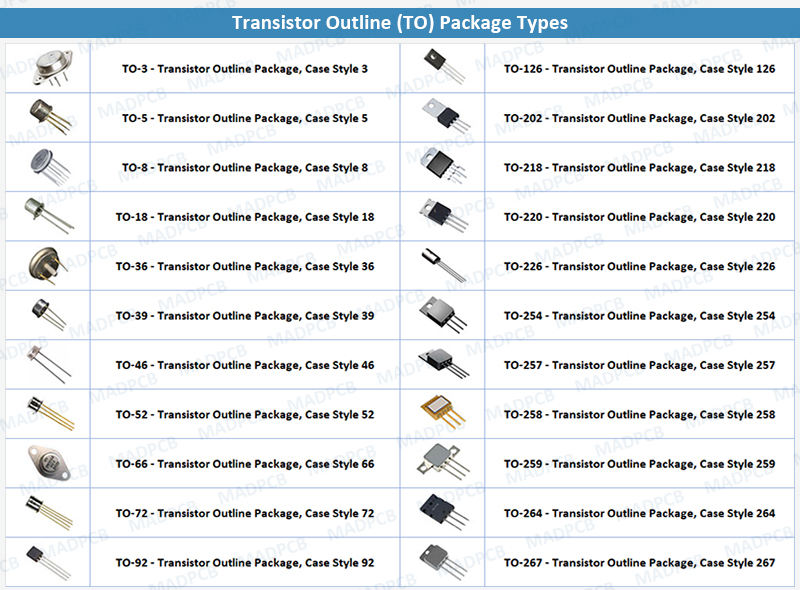

TO Transistor Packages

Transistor packages are designated by size and configuration. The most common package identifier consists of the letters TO (Transistor Outline) followed by a number. Because of large assortment of transistor packages available, it is difficult to develop rules for identifying the emitter, base, and collector leads of each device. It is best to refer to the manufacturer’s datasheet to identifying the leads of each device.

Transistor packages are the styles of case used to house transistor components, providing the connection between the die and the external circuit, as well as protection for the delicate die and perhaps capacity for removal of heat via heatsinks to avoid thermal damage.

TO Header and TO Cap

The TO Package is an industrial standard that regulates the design and size of current-conducting microelectronic packaging and housings consisting of a TO header and a TO cap.

The TO header delivers a mechanical basis for the installation of electronic and optical components, such as semiconductors, laser diodes, or simple electronic circuits, while at the same time providing power to the encapsulated components with the aid of pins. Two types of TO caps – molded TO caps and soldered TO caps – protect the optical components of transmission as well as reception applications, and they ensure the transmission of the optical signals by acting as an optical interface. Therefore, the properties of the installed windows or lenses must fulfill extremely high requirements.

TO headers and caps are then welded together to form a TO housing where the process removes the oxygen inside the encapsulated spaces to protect against corrosion. Customized solutions are available for both high-volume TO headers and microelectronic (or hybrid) packages.