12 Layer Every Layer Interconnect (ELIC) Rigid-Flex PCB for Tablet

12 Layer Every Layer Interconnect (ELIC) Rigid-Flex PCB for Tablet

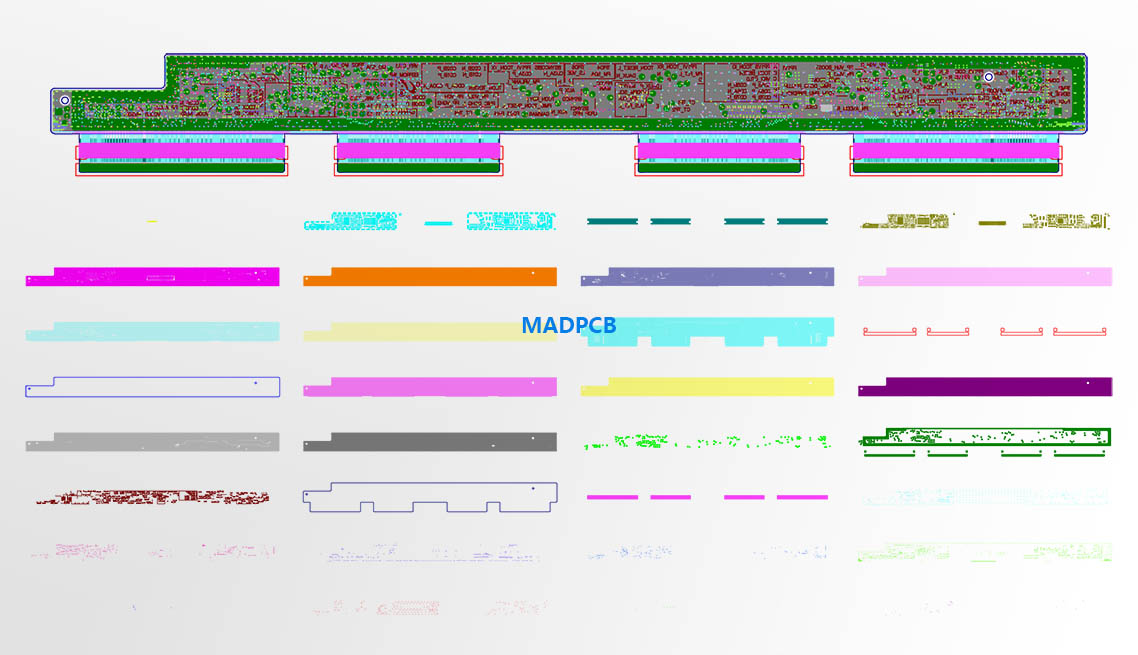

With multilayer PCBs containing even more layers and becoming thinner than ever before, new techniques are used to increase interconnect density. Every Layer Interconnect (ELIC) is one technology that lets PCB designers create very thin, flexible PCBs with high functional density. These advanced HDI boards contain multiple layers of copper-filled stacked in-pad microvias that enable even more complex interconnections.

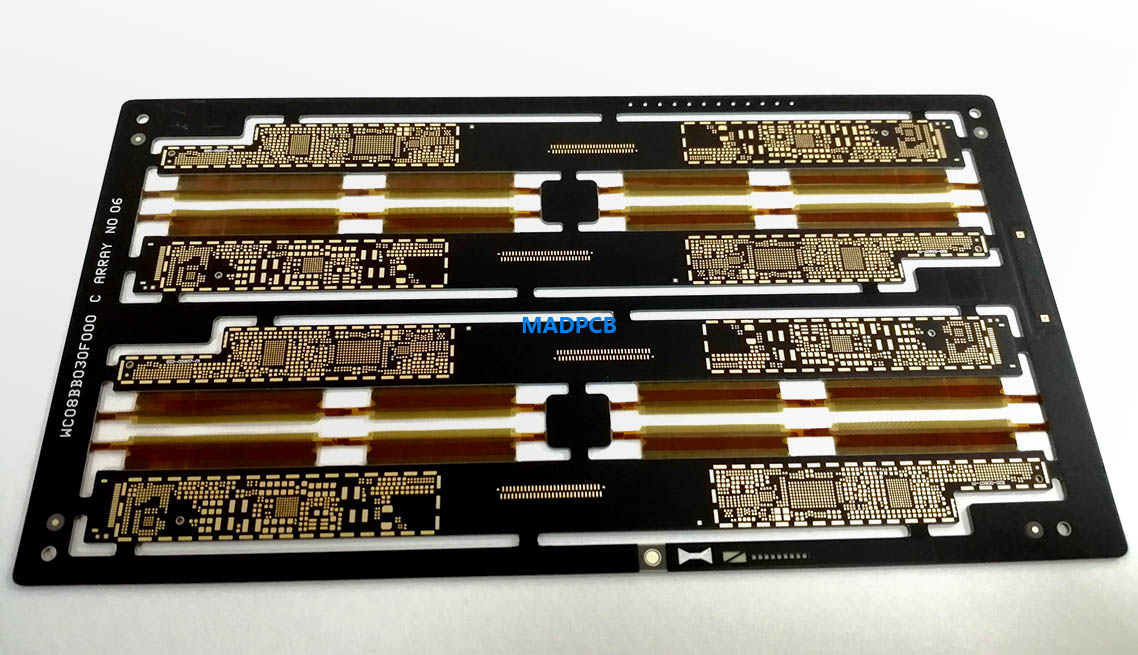

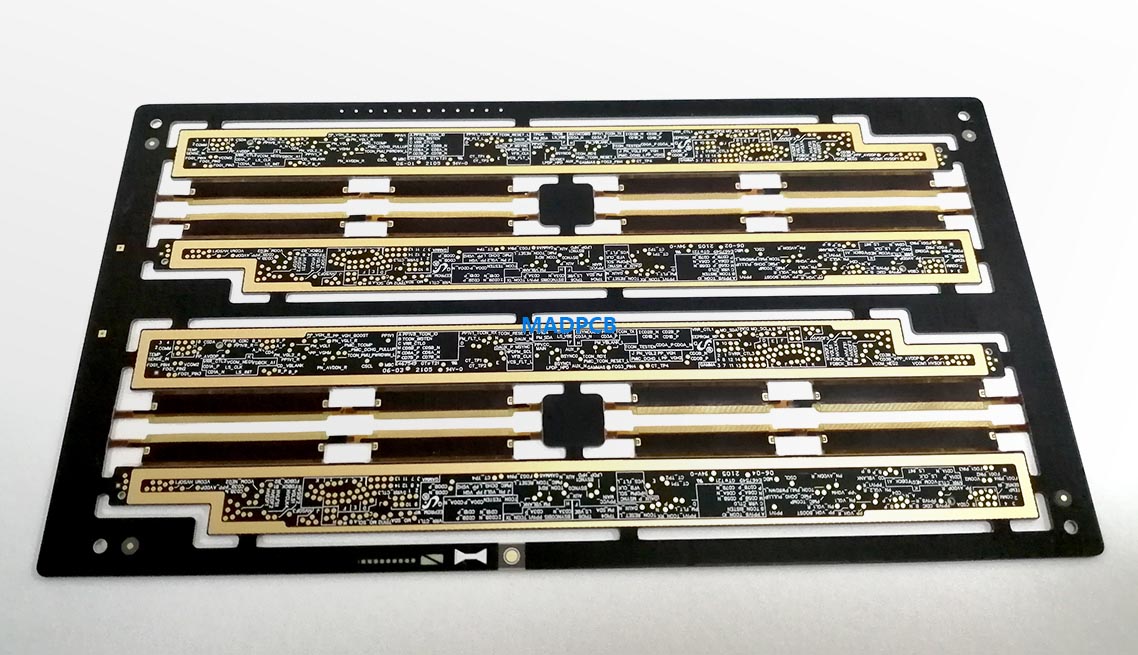

MADPCB has capabilities to design, manufacture and assemble every layer interconnect (ELIC) HDI PCB boards. Here is a 12-layer ELIC rigid-flex PCB for tablet (820-00907-01).

- Layer Count: 12 (6R+1F+5R)

- HDI Type: Every Layer Interconnect (ELIC)

- Material: PI FCCL + FR-4 Tg150, 94V-0, RoHS

- Finished FPC + Stiffener Thickness: 0.15mm

- Finished Rigid-Flex Board Thickness: 0.8mm

- Solder Mask: Black Matte x2

- Coverlay: Yellow

- EMI Shielding Film: Black

- Silkscreen: White x2

- Unit Size: 157.65*18mm

- Panel Size: 4up

- Finished Inner Copper Weight: 18μm

- Finished Outer Copper Weight: 30μm

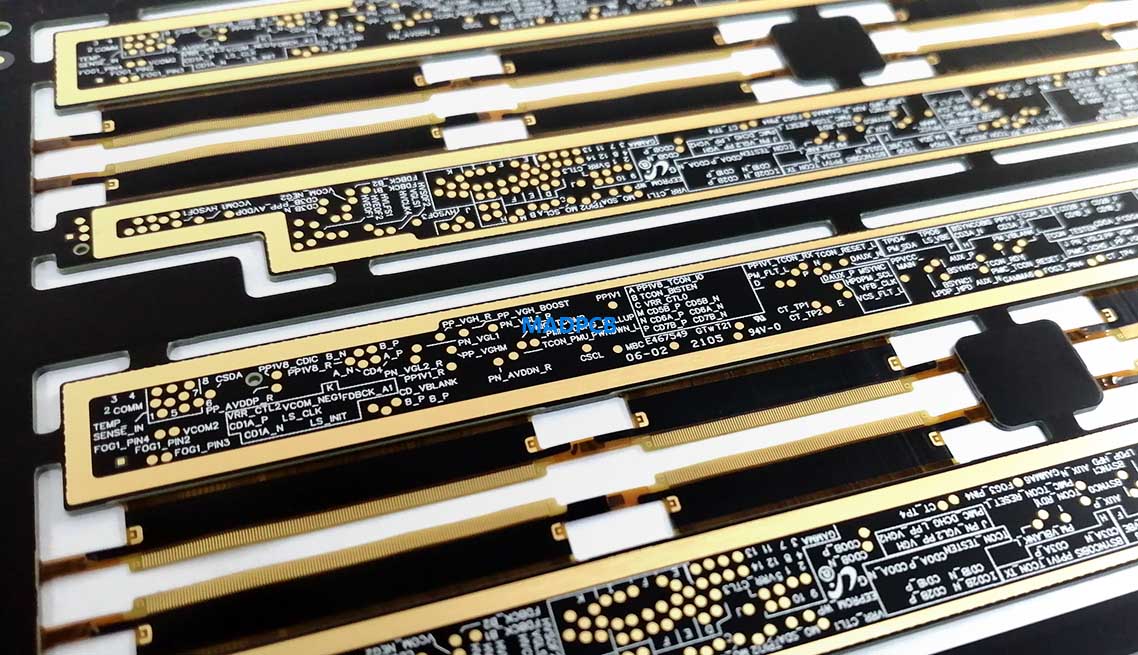

- Surface Finish: OSP + ENIG (Au: 2-3μ”, Ni: 120-240μ”)

- Min Trace Width/Spacing: 2.4mil/2.1mil

- Gold Finger Width: 3.9mil

- Via-in-Pad: Resin filled + Copper Capped

- Controlled Impedance: Yes

ELIC is sometimes referred to as any-layer HDI. When using ELIC on an HDI board, each layer has its own copper-filled, laser-drilled microvias. ELIC uses only stacked copper-filled microvias to make connections through each layer. This allows connections to be made between any two layers in the PCB once the layers are stacked. Not only does this offer an increased level of flexibility, but it also allows designers to maximize the interconnect density.