What’s Ceramic CGA?

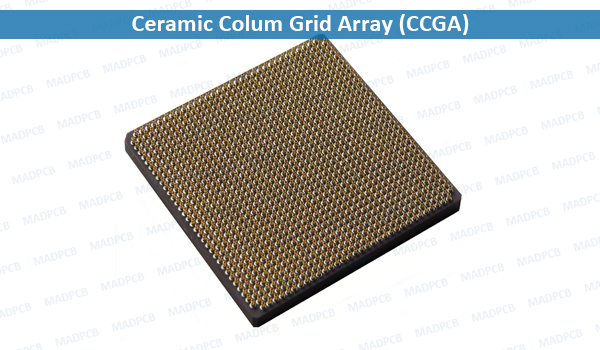

Ceramic Colum Grid Array (CCGA) is a square-shaped or rectangular ceramic package that uses solder columns for external electrical connection instead of leads or solder balls. These solder columns are arranged in a grid array at the bottom of the ceramic package body, hence he name “ceramic column grid array”. The CCBGA is basically just a CBGA package that has solder columns instead of solder balls.

The main advantage of CCGA over CBGA is the higher reliability of the solder columns compared to solder balls. The columns provide a higher package stand-off and structural flexibility, allowing the CCGA to adapt to CTE mismatches with the PCB more easily than CBGA’s.

The CCGA package is designed for high I/O applications, with column counts typically ranging from 191 to 2577. Column pitch (distance between solder columns) values typically used by the CCGA package are 1.0mm and 1.27mm. Typical body sizes range from 14mm square to 52.5mm square. The height of the solder column from the ceramic body of the Ceramic CGA is typically either 1.27mm or 2.2mm.

| Properties of Some CCBGAs | |||

| No. of Columns | Body Size | Package Thickness | Column Pitch |

| 376 | 27.94 mm x 27.94 mm | 2.79 mm | 1.27 mm |

| 376 | 27.94 mm x 27.94 mm | 2.79 mm | 1.27 mm |

| 624 | 32.5 mm x 32.5 mm | 2.5 mm | 1.27 mm |

| 1152 | 35 mm x 35 mm | 3 mm | 1.0 mm |

| 1272 | 37.5 mm x 37.5 mm | 3 mm | 1.0 mm |