What Is Cold Spot in PCB Assembly?

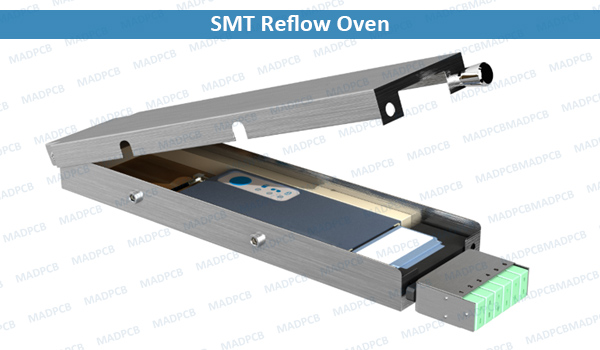

SMT Cold Spot is an area that does not get sufficient heat from reflow oven to activate the flux at the right time and allow the solder to reach molten stage and thus reflow. The main reason for a Cold Spot is when Thin Chip components such as resistors are placed next to or between large/high bodied components. This causes what’s known as a shadowing effect where large components effectively shadow the smaller components from the heat in the reflow oven. To avoid this type of issues ensure that smaller components should not placed too close to large components. A good thermal profiling setup through reflow profiler would be a best solution to prevent such reflow failure before put your boards into reflow soldering.

For getting high quality PCB assembly manufacturing, feel free to contact MADPCB for quick quote first.