What’s Fine Pitch Technology?

Fine Pitch Technology (FPT) is the term used to describe the printed circuit board (PCB) assembly technology for a family of integrated circuit (IC) packages distinguished by the fine spacing between their small leads. Fine Pitch packages are defined as those surface-mount components with lead spacings of 0.65mm (26mil) or less. Also see Ultra Fine-Pitch.

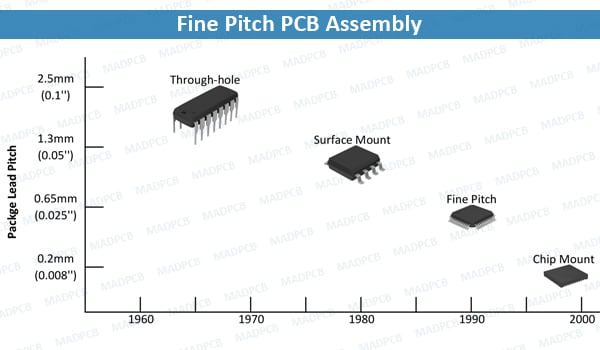

From the 1960s until the mid-1980s through-hole assembly was the prevailing method. Then surface mount (SMT) became the dominant package ad assembly methodology, offering significant size savings but mixed cost savings. Fine pitch is becoming the major method for the 1990s, as it provides size and cost savings for many users. Fine-pitch packages are an essential link in the evolutionary chain. However, the revolutionary proliferation of different fine-pitch package types that has occurred will not hasten their acceptance.

FPT and CMT

Beyond FPT, direct chip mounting (CMT) techniques will emerge as the dominant technology. Early CMT assemblies are taking form as multichip modules and simple chip on board (COB) subassemblies. CMT will replace FPT when reliable bare integrated circuits are available and a CMT infrastructure develops.

The increase in the number of leads for a given increase in integrated circuit functionality is predicted by an algorithm known as Rent’s Rule. Rent’s Rule states that the number of package leads needed is a function of the number of logic circuits in the package.

FPT packages will, in time, be used in all applications incorporating electronics. Today, FPT is associated closely with applications specific ICs, high lead count microprocessors and math coprocessors, and high-density memory applications. FPT BGAs and chip scale packages have been developed as an alternative to direct flip chip attachment for high-density electronics. The larger solder sphere diameter and higher standoff of CSPs and FPT BGAs improve thermal cycle reliability while the larger pitch relaxes wiring congestion on the printed circuit board (PCB). FPT BGAs and CSPs also allow rework to replace defective devices. Thermal cycle reliability has been shown to meet many consumer application requirements. However, FPT BGAs and CSPs have difficulty passing mechanical shock and substrate flexing tests for portable electronics applications.

Fine Pitch PCB Assembly

With most electronic equipment trending towards compact designs, circuit boards inside them must support a substantial number of components per unit square area. With components packed so close together, designs are usually on the extremes and manufacturers must follow tight PCB fabrication and tolerances. Another feature of these designs is the use of components with very high pin count, leading to very fine pin pitch between the pins. This is the origin of the name small pitch PCB assembly, another name being high density PCB assembly.

At MADPCB, we design, manufacture and assemble fine pitch PCBs. As per our experience, following a few simple generic rules significantly increase the chances of a successful assembly of fine circuit boards. In FPT PCB assembly, the center-to-center distance between adjacent SMD pads and solder balls are extremely small. High density FPT components placement with high precision will be a challenge for SMT manufacturer. Check our PCB assembly process and capabilities.