What’s PBGA?

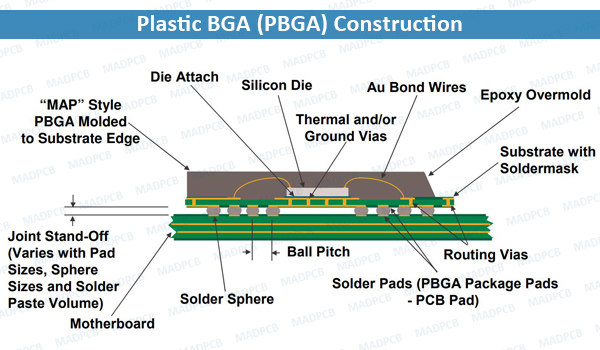

Plastic Ball Grid Array (PBGA) package incorporate the most advanced assembly processes and designs for cost/performance applications. This advanced IC package technology allows application and design engineers to optimize innovations while maximizing the performance characteristics of semiconductors.

PBGA packages are designed for low inductance, improved thermal operation and enhanced SMT ability. Custom performance enhancements, like ground and power planes, are available for significant improvements in electrical response demanded by advanced electronics. Additionally, these packages utilize industry proven, semiconductor grade materials for reliable, long-term operations while providing user flexible design parameters.

The integrated design features of PBGAs offer enhanced performance in many devices, making this the ideal package for: microprocessor, microcontrollers, ASICs, gate arrays, memory, DSPs, PLDs, graphics and PC chip sets. Applications requiring improved portability, formfactor/size and high-performance such as cellular, wireless telecommunications, PCMCIA cards, Global Positioning Systems (GPS), laptop PCs, netbooks, video cameras, disc drives and similar products benefit from PBGA attributes.

PGBA Features

- Custom ball counts to 1521

- 1.00mm, 1.27mm and 1.50 mm standard ball pitch available, other ball pitches available upon request, (e.g. 0.8 mm)

- 17 mm to 40 mm body sizes

- Thin Au wire or Cu wire compatible

- Chip-on-Chip (CoC)

- Large mold cap for quality enhancement

- Low profile and lightweight

- Thermal and electrical enhancement capable

- Highly flexible internal routing of signal, power, and ground for device performance and system compatibility

- HDI designs possible

- Suitable substrate for multi-die (MCM) and integrated SMT structures

- Mature strip-based manufacturing process with high yields

- Full in-house design capability

- Quickest design-to-prototype delivery

- Perimeter, stagger and full ball arrays

- Special packaging for memory available

- Multi-layer, ground/power

- JEDEC MS-034 standard outlines

- Excellent reliability

- 63 Sn/37 Pb or Pb-free solder balls

- Automotive AEC-Q100 Compliance

MADPCB is a contract manufacturer (CM), provides PCB fabrication, assembly (including advanced BGA assembly), and design services.

| Package Terminology | ||

| PBGA | Plastic Ball Grid Array (BGA) | Can be either 2 layer or 4 layer substrates; BGA pitch range from 1.0-1.27mm; Body size >23mm x 23mm |

| TEPBGA | Thermally Enhanced PBGA | 4 layer substrate with 2oz Cu inner layers for increased thermal performance |

| TEPBGA-2 | Thermally Enhanced PBGA with Embedded Heatspreader |

TEPBGA plus heatspreader over die |

| MAP | Mold Array Package | A type of PBGA, except mold cap covers entire topside surface; BGA pitch range from 0.5-1.0mm; Body size <19mm x 19mm |