What’s PDIP?

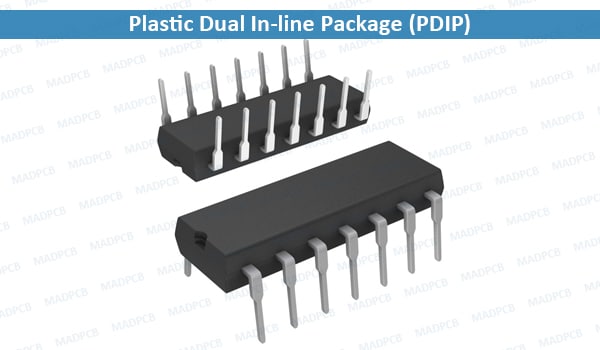

Plastic Dual In-line Package (PDIP) is one of the most mature plastic IC packages still in use today. It is rectangular in shape and has leads extending from both sides along its length, thus forming two sets of in-line pins.

Plastic DIP (PDIP) packages are usually sealed by fusing or cementing the plastic halves around the leads, but a high degree of hermeticity is not achieved because the plastic itself is usually somewhat porous to moisture and the process cannot ensure a good microscopic seal between the leads and the plastic at all points around the perimeter. However, contaminants are usually still kept out well enough that the device can operate reliably for decades with reasonable care in a controlled environment.

The PDIP comes in two body widths, i.e., 300 mils and 600 mils. Lead counts range from 8 to 64. It is a through-hole package, which means that its leads protrude to the other side of the circuit board once mounted. It is robust and resistant to moisture, but it is also much bulkier than its modern successors. A ‘shrink‘ version of the Plastic DIP exists and is known as the SPDIP.

| Properties of Some Examples | |||||

| Lead Count | Width | Length | Thickness | Pitch | Max. Height |

| 8 | 6.52mm | 9.53mm | 3.24mm | 2.54mm | 4.19mm |

| 10 | 6.61mm | 22.86mm | 3.94mm | 2.54mm | 4.95mm |

| 12/16 | 6.61mm | 29.91mm | 3.94mm | 2.54mm | 5.33mm |

| 22 | 13.53mm | 37.4mm | 7.75mm | 2.54mm | 8.89mm |

| 24 | 13.71mm | 31.75mm | 4.57mm | 2.54mm | 5.08mm |

| 28 | 13.525mm | 37.4mm | 4.07mm | 2.54mm | 6.35mm |