What is a Rectifier?

A Rectifier is an electrical device, which converts alternating current (AC), which periodically reverses direction, to direct current (DC) by allowing a current to flow through the device in one direction. The reverse operation is performed by the inverter.

Rectifiers can take a wide variety of physical forms, from vacuum tube diodes and crystal radio receivers to modern silicon-based designs.

The simplest rectifiers, called half-wave rectifiers, work by eliminating one side of the AC, thereby only allowing one direction of current to pass through. Since half of the AC power input goes unused, half-wave rectifiers produce a very inefficient conversion. A more efficient conversion alternative is a full-wave rectifier, which uses both sides of the AC waveform.

Bridge Rectifier Circuits

The bridge rectifier is an electronic component that is widely used to provide full wave rectification and it is possibly the most widely used circuit for this application.

Using four diodes the bridge rectifier the circuit has a distinctive format with the circuit diagram based on a square with one diode on each leg.

In view of its performance and capabilities, the full wave bridge rectifier is used in many linear power supplies, switch mode power supplies and other electronic circuits where rectification is needed.

A diagram of the basic bridge rectifier circuit has a bridge rectifier block at the center. This consists of a bridge circuit which includes four diodes. These can be individual diodes, or it is also easy to obtain bridge rectifiers as a single electronic component.

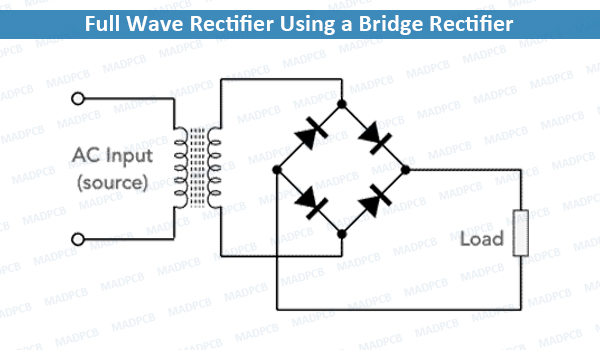

Full Wave Rectifier Using a Bridge Rectifier

The bridge rectifier provides full wave rectification and has the advantage over the full wave rectifier using two diodes that no center tap is required in the transformer. This means that a single winding is used for both halves of the cycle.

Wound electronic components are expensive and including a center tap means that two identical windings, each providing the full voltage are needed to provide the full wave rectification. This doubles the number of turns and increases the cost of the transformer. This can be particularly important when designing linear power supplies or other electronic devices.

To see how the bridge diode full wave rectifier operates it is useful to see the current flow over a compete cycle of the incoming waveform.

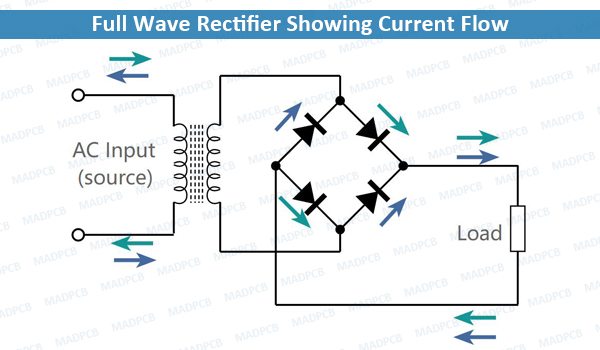

Full Wave Rectifier Showing Current Flow

In most power supply applications, whether for linear voltage regulators, or for switch ode power supply applications, the output from a bridge rectifier will be connected to a smoothing capacitor as part of the load.

These electronic components accept charge during the high voltage parts of the waveform and then give out charge to the load as the voltage falls. In this way they provide a more constant voltage than the direct output from the bridge rectifier. This allows other circuits like the linear voltage regulators and switch mode power supplies to operate correctly.

In terms of the bridge rectifier and its diodes, the inclusion of the capacitor means that the current taken through the diodes will have significant peaks as the capacitor charges up.

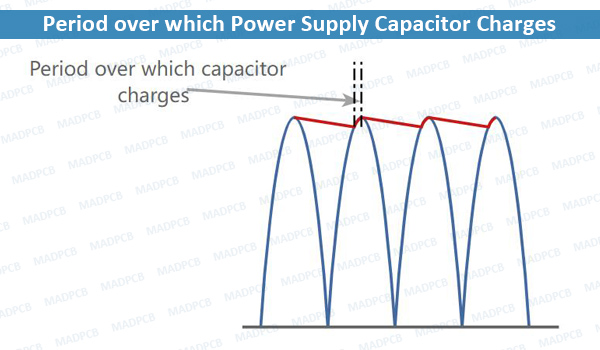

Period over which Power Supply Capacitor Charges

When selecting the electronic components for the bridge rectifier, it is necessary to ensure that they can accommodate the peak current levels.

Bridge Rectifiers

The bridge rectifier components can come in a variety of forms. They can be made using discrete diodes. A ring of the four diodes can easily be made either on a tag or as part of a printed circuit board. Care must be taken to ensure that the diodes are sufficiently ventilated as they can dissipate heat under load.

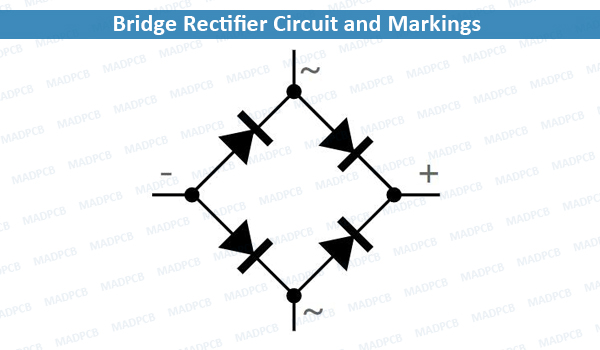

Bridge Rectifier Circuit and Markings

Alternatively bridge rectifiers come as single electronic components containing the four diodes in a single block or encapsulation. The four connections are brought out and marked “+”, “-” and “~”. The “~” connection is used to connect to the alternating input. The + and – connections are obvious.

Some of these bridge rectifiers are intended for mounting on a printed circuit board and may have wires for through hole mounting. Others may be surface mount devices.

Some bridge rectifiers are contained in larger encapsulations and are intended for mounting on a heat sink. As these rectifiers are designed to carry significant levels of current, they can dissipate significant levels of heat as a result of the diode drop and also the internal resistance of the bulk silicon used for the diodes.

Rectifier Applications

Rectifiers are fundamental to how many different devices operate. Because the standard electrical distribution grid uses AC power, any device that runs on DC power will require a rectifier to function correctly. Virtually all modern electronics need the steady, constant power of DC to operate correctly.

Additionally, we use rectifiers to change voltage in DC power systems. Because it is relatively difficult to convert DC voltage directly in some scenarios, the simplest solution may be the following process:

- Convert DC to AC

- Change the voltage using a transformer

- Convert AC back to DC using a rectifier

In a few applications, the rectifier itself serves a direct function beyond converting AC to DC. Take, for example, one of the earliest radio designs: a crystal radio. This device employed a fine wire pressed against a crystal (we would now refer to this component as a diode), which rectified the alternating current radio signal directly, thus extracting the audio and producing sound in earphones. Precision rectifiers are still in use in some types of radios today.

Flame rectification is another example of applying rectification directly. In this application, a flame acts as a rectifier due to the differential in mobility between electrons and positive ions present in a flame. We use the rectifying effect of fire on AC in gas heating systems to direct the flame’s presence.

Finding a PCB design company, which can provide PCB manufacturing, Parts sourcing, PCB assembly services? Why not contact MADPCB? a one-stop PCB services provider in Shenzhen, China. Get in touch with our professional sales engineer when in demand.