Display Board Assembly with Electrical and Software Testing Services

Display Board Assembly with Electrical and Software Testing Services

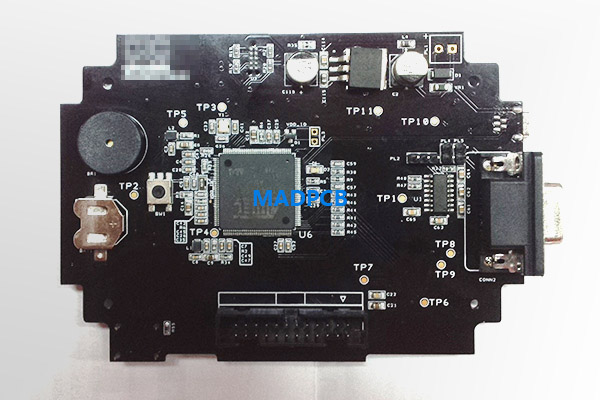

Gerber files, BOM, Coordinates, Assembly Drawings, Program, Software and testing procedures of this display PCB board are provided by customer, and MADPCB complete all electronics manufacturing jobs, including PCB manufacturing, BOM sourcing, assembly, IC programming, program uploading, debug, electrical and software testing.

The testing procedures are detailed for the electrical and functional testing of the display board. The board drives a 4.3 inches screen panel, it has an RTC on board, some Flash memory and some EEPROM memory. Testing procedure requires a touchscreen display (ATOPS AT043B35-15-10-TP) and a test board. The daughter test board will be used to power up the display PCB board at DC 5V.

- Layer Count: 6 layers

- Material: FR4 Tg150

- Finished Board Thickness: 1.2mm +/-10%

- Solder Mask: Black x2

- Silkscreen: White x2

- Finished Inner Copper Weight: 35μm

- Finished Outer Copper Weight: 35μm

- Surface Finish: Immersion Gold

- Assembly Process: Lead-free Assembly

- IC Programming: Yes

- Firmware Uploading: Yes

- Software Testing: Yes

- Electrical Testing: Yes

- Functional Testing: Yes