Table of Contents

IPC-4761 Via Protection: Via Tenting, Via Plugging, Via Filling

Several technical or production-related demands for PCB manufacturing require via protection. These types of via covering are possible:

- Simply Covering: Via Tenting or Tented Vias

- Partially Filled: Via Plugging or Plugged Vias

- Completely Filled: Via Filling or Filled Vias

In the following, you will find a comparison of the technical capabilities of via covering protection. The reference is the IPC-4761 [Design Guide for Protection of Printed Board Via Structures]. The following chart is a summary of the different types of via plugs called out in this document, which reflects the IPC effort to standardize the via covering protection process:

| Type | Description | Via Covering Material |

|

I-a I-b |

Tented Via (one-sided)

Tented Via (double-sided) |

Dry film solder mask |

|

II-a II-b |

Tented & Covered Vias (one-sided)

Tented & Covered Vias (double-sided) |

Dry film solder mask + LPI solder mask |

|

III-a III-b |

Plugged Via (one-sided)

Plugged Via (double-sided) |

Plugging Epoxy (non-conductive paste) |

|

IV-a IV-b |

Plugged & Covered Via (one-sided)

Plugged & Covered Via (double-sided) |

Plugging Epoxy + LPI solder mask |

| V | Filled Via | Plugging Epoxy (non-conductive paste) |

|

VI-a VI-b |

Filled & Covered Via (one-sided)

Filled & Covered Via (double-sided) |

Plugging Epoxy + LPI solder mask |

| VII | Filled & Capped Via | Special Plugging Epoxy + Copper Plating to planarization. |

Via Tenting

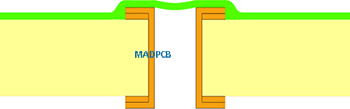

IPC-4761 Type I: Tented Via

Dry film solder mask is stretched over the Via. No other materials are added.

One-sided: Type I-a

Double-sided: Type I-b

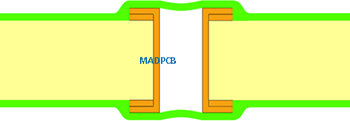

IPC-4762 Type II: Tented & Covered Via

The via is completely covered with dry film solder mask and overprinted with normal solder mask, afterwards.

One-sided: Type II-a

Double-sided: Type II-b

Application

- Protect of solder paste floating up to the component side

- Enables vacuum-adaption for production

- Covering of critical vias, e.g. beneath BGA

Alternatives

You can apply Via Filling, alternatively in via protection.

Through cutting the solder mask clearance, you can ensure a sufficient solder mask bridge for BGAs. Using this method, the via annular rings will be partly covered with solder mask.

Parameters

| Covering | Max. Drill Diameter |

| Via Tenting | 0.3mm |

Designation

It is sufficient to cover the vias within the solder mask layer.

Via Plugging

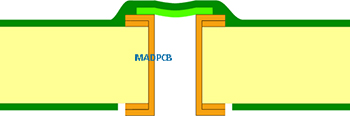

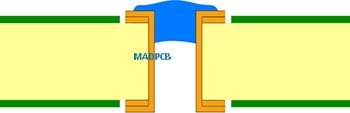

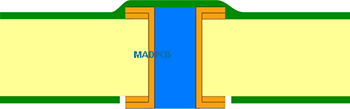

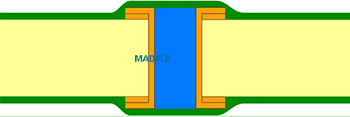

IPC-4761 Type III: Plugged Via

The via is partially filled with non-conductive paste.

One-sided: Type III-a

Double-sided: Type III-b

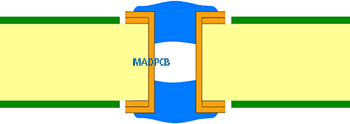

IPC-4761 Type IV: Plugged & Covered Via

The via is partially filled with non-conductive paste and overprinted with normal solder mask, afterwards.

One-sided: Type IV-a

Double-sided: Type IV-b

Multi-layer PCB recommends one-sided plugging (Type III-a / Type IV-a) as there is a chance of cracks through encapsulated gas while soldering double-sided plugged vias..

Application

- Protection of solder paste floating up to the component side.

- Enables vacuum-adaption for production.

Parameters

| Covering | Min Drill Diameter | Max Drill Diameter |

| Via Filling | 0.25mm | 0.5mm |

Designation

Copy the vias to be filled into an additional layer and define that layer with your PCB fabrication notes.

Via Filling

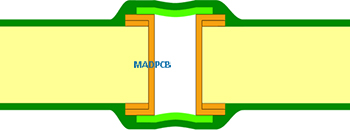

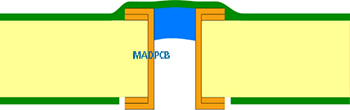

IPC-4761 Type V: Filled Via

The via is filled completely with non-conductive paste.

IPC-4761 Type VI: Filled & Covered Via

The via is filled completely with non-conductive paste and overprinted with normal solder mask, afterwards

One-sided: Type VI-a

Double-sided: Type VI-b

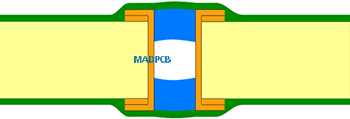

IPC-4761 Type VII: Filled & Capped Via

The via is plated-through and cleaned -afterwards a non-conductive paste is forced in and hardened -the ends are planarized, metallized and plated-over. Hence, the surface is planar and solderable.

Via Filled and Capped Technology is mostly used for Via-in-Pad (VIP) solutions and is also applied for stacked and staggered via & microvia in HDI boards. Via plugging facilitates routing of additional conductor traces between BGA vias amongst other things.

Filled & Capped Vias are also possible for Blind Vias.

Application

- Space saving

- Protection of solder floating up to the component side.

- Protection of solder floating up to the component side.

- Facilitates stacked and staggered Microvia for sequential build-up (SBU) multilayers.

- Facilitates Via-in-Pad Technology, e.g. for BGAs.

Parameters

| Covering | Min Drill Dia. | >Pad Dia. | Max Drill Dia. | >Pad Dia. | Aspect Ratio |

| Filled & Capped

IPC-4761 Type VII |

0.15mm | 0.35mm | 0.4mm | 0.6mm | 1:12 |

| Filled & Capped

eletroplated |

0.1mm | 0.3mm | – | – | 1:10 |

*Filled & Capped Vias blind vias have an aspect ratio of 1:1.

Designation

Copy the vias to be plugged into an additional layer and define that layer with your solder paste.

MADPCB strongly recommends that all vias be tented, filled and/or capped, especially under BGA packages according to IPC-4761 covering protection.