What Is a Rotary Switch?

A Rotary Switch is an electromechanical switch operated by rotation that has a rotating shaft connected to one terminal capable of making or breaking a connection to one or more other terminals.

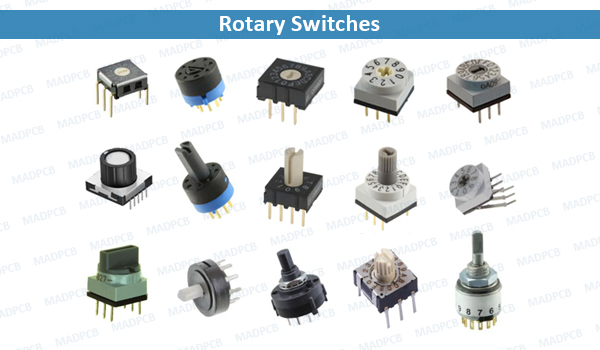

Rotary Switches

A rotary switch consists of a spindle or “rotor” that has a contact arm or “spoke” which projects from its surface like a cam. It has an array of terminals, arranged in a circle around the rotor, each of which serves as a contact for the “spoke” through which any one of a number of different electrical circuits can be connected to the rotor. The switch is layered to allow the use of multiple poles; each layer is equivalent to one pole. Alternatively the rotation can be limited to a fraction (half; third etc.) of a circle and then each layer can have multiple (two; three etc.) poles. Usually, such a switch has a detent mechanism so it “clicks” from one active position to another rather than stalls in an intermediate position. Thus a rotary switch provides greater pole and throw capabilities than simpler switches do.

Modern rotary switches use a “star wheel” mechanism to provide the switching positions, such as at every 30, 45, 60, or 90 degrees. Nylon cams are then mounted behind this mechanism and spring-loaded electrical contacts slide around these cams. The cams are notched or cut where the contact should close to complete an electrical circuit.

Some rotary switches are user-configurable in relation to the number of positions. A special toothed washer that sits below the holding nut can be positioned so that the tooth is inserted into one of a number of slots in a way that limits the number of positions available for selection. For example, if only four positions are required on a twelve position switch, the washer can be positioned so that only four switching positions can be selected when in use.

Construction

Rotary switches may feature different switch positions that can be set by rotating the switch spindle in one or another direction. Some common examples where a rotary switch might be used is in a multi-speed fan or as a band selector on multi-band radios. Until the early 1970’s, rotary switches were used as channel selectors on TV receivers.

In general, rotary switches can be found where ever there is a need to control a large number of circuits covering a range of currents, voltages and power requirements. Currently, you will find rotary switches in these applications:

- medical equipment

- computers

- industrial controls

- instrumentation

- communications equipment

- aircraft equipment

The construction and design of a rotary switch is centered around the center rotor. The rotor has a contact arm that projects out from its surface. Around the rotor are an array of terminals. These serve as the contact for the arm, or spoke. Since the switch has multiple layers, each layer permits the use of an additional pole. There is also a detent mechanism which will click into place as the switch is turned from one active position to another. The contact / sensor system and detent mechanism determine the number of possible switching combinations.

Rotary Switch Types

There are many different types of rotary switch for choice in PCB design and assembly. Here are some of the most widely-used:

- Wafer Switches: Wafers are components in most rotary switch models that distribute electricity from the spindle to the output terminals. Rotary wafer switches are a special design in which contacts are arranged on both sides of the wafer.

- Yaxley Switches: Yaxley switches are a traditional rotary switch design, now little used.

- Miniature Rotary Switches: Mini rotary switches are designed for use in settings where space is at a premium, for example, circuit boards. Typically, they are fully open or fully closed and often used as sensors to detect the position of other parts.

- High Current Rotary Switches: High current rotary switches are specially designed for higher voltages. They are made from materials resistant to electrical discharge such as ceramics and both the casing and contact points are reinforced.

- Rotary Cam Switches: Rotary cam switches feature a shaft that increases or decreases electrical resistance in the attached contact points when turned. They are a good choice for electronic instruments with variable currents.

- Rotary DIP Switches: Rotary DIP switches are groups of switches aligned in a dual in-line package, a standard configuration typically used on printed circuit boards and in other electronic components. Also known as dual-in-line (DIL) switches, they are used to adjust the electrical response of the device in which they are installed.

- Binary Rotary Switches: Binary rotary switches are another miniaturized design for use in delicate electronic equipment. They use a binary on-off system.

- Momentary Rotary Switches: Momentary rotary switches are used in a variety of electrical circuits to provide a momentary change of state function, such as switching from one circuit to another or from on to off. A momentary switch returns to a default position after being pressed.

- PCB Mount Rotary Switches: PCB mount rotary switches are upright controls mounted on printed circuit boards (PCBs). They are used to control multiple output terminals.

- Heavy-Duty Rotary Switches: Heavy-duty rotary switches are designed to provide robust mechanical control in demanding industrial environments.

Available rotary switch accessories and add-ons include:

- Replacement dials, caps and knobs

- Rotating open circuits

- Shaft assemblies and spindles

- Lock mechanisms

Contact Configuration – Poles, Positions & Ways

Contact points in an electrical circuit are called terminals. The electrical entry point – or input terminal – on a rotary switch is called a pole, and some designs feature more than one, each connecting via rotation to a series of output terminals, called ways. Most rotary switches feature 3-way, 4-way, 6-way or 12-way configurations, but higher numbers are available. The switching position – the point at which a switch interacts with a circuit – is called a throw.

Different configurations of rotary switches have different combinations of poles, ways and throws. Some of the most common include:

- Double pole double throw (DPDT) rotary switches. Two on-on switches which work in conjunction

- Double pole four throw (DP4T) rotary switches. These are widely used in radios, TVs, home lighting systems and industrial settings

- 8-pole rotary switches. This widely used design offers an easily selectable choice of input terminals or poles

- 2-pole 2-position rotary switches. In this rotary switch design, the dual poles are connected to the two selectable positions

- 2-pole 6-position rotary switches. In this design, each pole is wired to three selectable positions

- Multi-pole rotary switches. Standard rotary switch designs feature a single pole. Multi-pole models offer greater versatility

- Double pole three throw (DP3T) rotary switches. In this design, two separate circuits intersect at three different points, providing three selectable switch positions