What Is Dual in-line?

In microelectronics, a dual in-line package (DIP or DIL), or dual in-line pin package (DIPP) is an electronic component package with rectangle housing and two parallel rows of electrical connecting pins. The package may be through-hole mounted to a printed circuit board (pin) or inserted in a socket.

History

The dual-inline format was invented by Don Forbes, Rex Rice and Bryant Rogers at Fairchil R&D in 1964, when the restricted number of leads available on circuit transistor-style packages became a limitation in the use of integrated circuits. Increasingly complex circuits required more signal and power supply leads; eventually microprocessors and similar complex devices required more leads than could be put on a DIP package, leading to development of higher-density chip carriers. Furthermore, square and rectangular packages made it easier to route printed circuit traces beneath the packages.

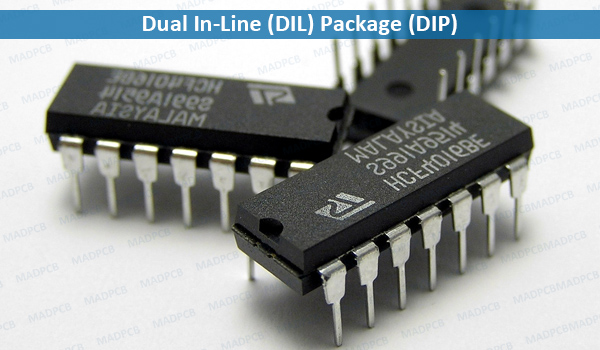

Dual In-Line Package (DIP)

A DIP is usually referred to as a DIPn, where n is the total number of pins. For example, a microcircuit package with two rows of seven vertical leads would be a DIP 14. Common packages have as few as three and as many as 64 leads. Many analog and digital integrated circuit types are available in DIP packages, as are arrays of transistors, switches, light emitting diodes (LEDs), and resistors. DIP plugs for ribbon cables can be used with standard IC sockets.

Dual In-Line packages are usually made from an opaque molded epoxy plastic pressed around a tin-, silver-, or gold-plated lead frame that supports the device die and provides connection pins. Some types of IC are made in ceramic DIP packages, where high temperature or high reliability is required, or where the device has an optical window to the interior of the package. Most DIP packages are secured to a PCB by inserting the pins through holes in the board and soldering them in place. Where replacement of the parts is necessary, such as in test fixtures or where programmable devices must be removed for changes, a DIP socket is used. Some sockets include a zero-insertion force (ZIF) mechanism.

Variations of DIP package include those with only a single row of pins, e.g. a resistor array, possibly including a heat sink tab in place of the second row of pins, and types with four rows of pins, two rows, staggered, on each side of the package. DIP packages have been mostly displaced by surface-mount package types, which avoid the expense of drilling holes in a PCB and which allow high density of interconnections, and which improves the SMT assembly efficiency.

Variants of Dual In-Line Package

Several DIP variants for ICs exist, mostly distinguished by packaging material:

- Ceramic Dual In-line Package (CERDIP or CDIP)

- Plastic Dual In-line Package (PDIP)

- Shrink Plastic Dual In-line Package (SPDIP)

- Skinny Dual In-line Package (SDIP or SPDIP)

EPROMs were sold in ceramic DIPs manufactured with a circuit window of clear quartz over the chip die to allow the part to be erased by ultraviolet (UV) light. Often, the same chips were also sold in less expensive windowless PDIP or CERDIP packages as one-time programmable (OPT) versions. Windowed and windowless packages were also used for microcontrollers, and other devices, containing EPROM memory. Window to prevent inadvertent erasure through exposure to ambient light.