Table of Contents

HDI PCB Layout Services

At MADPCB, we provide HDI PCB layout service globally. HDI layout is critical in many systems that have high component count and high net count. These HDI boards have enabled many multi-function products, such as mobiles, computers, networking and etc. PCB designers don’t normally plan to create an HDI PCB layout rules unless they are working with specific components that require such layout and routing skills. On the contrary, they are often forced to work in the HDI regime for a number of reasons. If you suspect you’ll need to work with component densities that require HDI layout and routing, MADPCB can provide technique support. Here is what you need to know.

What Is an HDI PCB Layout?

High density interconnect (HDI) layout refers to a set of techniques used to layout a printed circuit board when traces widths generally drop below 8mil 0.2mm). These techniques are designed to ensure you can fit a higher density of components onto a single board, allowed you to keep your board size small while increasing component count. Not all boards need HDI layout techniques of a number of reasons, while some components require HDI technique for proper routing.

A HDI board requires smaller vias to make layer transitions, particularly in fine-pitch BGA components and more traces per square mm. In order to accommodate fine-pitch components, you’ll find the following typical features in an HDI layout:

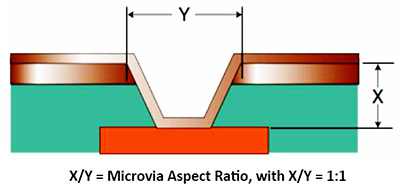

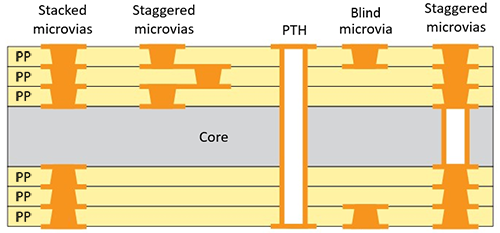

Microvias -Laser Ablated or Laser Drilled vias: HDI boards use laser drilled microvias, blind and buried, and staggered microvias for layer transitions. These microvias have smaller aspect ratios than typical through-hole vias. In order to use microvias with finer pitch components, their diameters are smaller, which then limits their useful depth.

- Thinner Traces: The thinner traces used in HDI boards are required to make connections to vias on each layer, as well as to in-pad vias. The thinner traces also allow higher density, thus the term HDI.

- Higher Layer Count: We’ve built non-HDI boards with high layer counts, but HDI PCB layer counts can easily reach more layers when working with high pin density components (e.g., FPGAs).

- Lower Signal Levels: HDI boards are not used for high voltage or high current. This is because the high field strength between neighboring lines will cause ESD, and high currents will cause excessive temperature rise in conductors.

If you look at the above points and the IPC standards, you can figure out when a PCB board makes the transition to the HDI regime, thus requiring HDI layout and routing skills. According to the IPC-2221A/IPC-2222 standards, the maximum recommended aspect ratio for through-hole vias is 8:1 (aspect ratio = via depth / via diameter). This means, for a standard thickness 1.6mm PCB, the minimum drill diameter for a through-hole via is 8mil (0.2mm). If your vias need to be smaller to accommodate fine-pitch components, then you’ll need to use some HDI-specific via designs and thinner traces.

Trace Sizes and Vias in HDI Layout

Clearly, the need to accommodate fine pitch components or simply a higher density of components is what motivates the need for HDI designs. Traces are fabricated in the same manner as traces on any other PCB board, although care is taken to prevent over-etching. Vias are a different beast and may require laser drilling for low aspect ratios through a single layer, known as blind or buried vias.

If you need to span multiple layers in an HDI board, you can’t use a through-hole via anymore and still comply with IPC standards. For larger diameter microvias, some PCB manufacturers has experience fabricating blind vias that span multiple layers, but this is not common. Furthermore, placing this in your PCB design will likely violate your PCB manufacturer’s DFM rules and will cause your PCB board receive no-bid status. Instead, vias can be placed in individual layers and stacked on top of each other (e.g., stacked microvias or blind-buried vias). The various microvia types in HDI PCB layout are shown below.

These different microvia types are primarily targeted at BGA components with different pitch. Once your BGA pitch gets to 32mil (0.8mm), you’ll likely be able to use a dog bone fanout with in-pad microvias. At 29.5mil (0.75mm) and less, you’re better off using plated in-pad microvias (VIPPO, via-in-pad plated over) to reach inner signal layers, although you can also route signals between BGA pads to reach the outer pad section during fanout. At much lower pitch (e.g. 20mil <0.5mm>). It is not recommended to route between pads unless your PCB supplier can reliably fabricate traces above 4mil (0.1mm).

Basic HDI PCB Design Guidelines

At MADPCB, when working with fine-pitch BGA, and the traces and vias that connect do it, there are some basic guidelines that apply to any HDI PCB layout.

- Check your PCB manufacturer’s capabilities. You should generally do this anyways before planning a new design, but nowhere else is this more important than in HDI design. Not all board manufacturers have the same capabilities in this area, and it’s best to check with your desired PCB manufacturer, like MADPCB, before you create an HDI layout that can’t be fabricated.

- Keep track of spacing between traces and pads. The same idea applied in 39.37mil (mm) pitch BGAs, the only point that change is scaling to microvia sizes. Solder mask clearance values are typically on the same size as your trace width. The solder mask clearance depends on the pad size and your pad pitch.

- Don’t use staggered vias or ELIC (every layer interconnect) if you don’t need them. The whole point of HDI routing is to provide as much space as possible for routing on the surface and inner layers. While it might be tempting to stack across the entire span of the substrate, don’t take up extra space unless it’s really necessary.

- Opt to fewer layers. High layer count boards bring more assembly steps and manufacturing costs. If you follow the previous guideline, you can significantly reduce the cost per board.

- Don’t forget about signal integrity when working with HDI boards. Any HDI layout will need to be designed with high speed design (HSD) guidelines in mind, or high frequency guidelines if you’re working with an RF PCB board. The same signal integrity rules that apply in typical PCBs that requires impedance-controlled routing, you’ll need to carefully design your traces and stack-up to ensure your impedance is consistent with your signal standard.

HDI layout and design routing requires working with the right design tools and an experienced design company. The design team at MADPCB has rich experience of designing HDI boards and standard boards in various application fields. Moreover, MADPCB is a one-stop PCB solutions provider, offers PCB design, fabrication and assembly. With our value-added service, you also can rely on MADPCB to provide IC programming and functional testing for your PCB designs in prototype PCB and high-volume runs.