Table of Contents

PCB Design Services

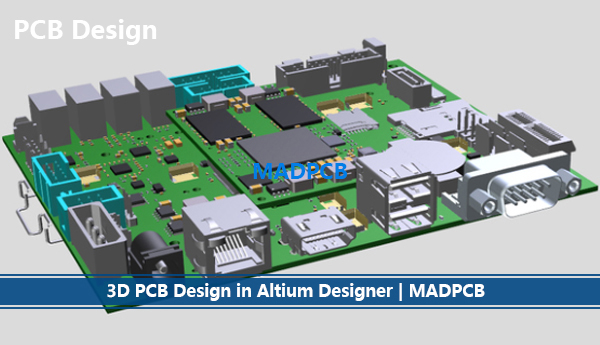

MADPCB provides PCB design services to customers through gathering talent PCB designers with over 10 years’ experience in high speed digital, analog, mixed-signal and RF systems. We design single, double, and high layer count (up to 30 layers) rigid, IMS (or metal core), flexible and rigid-flex printed circuit boards with thru-hole, blind and/or buried vias, micro-via, back drilling techniques. Whether your project requires high speed constraint-driven requirements, routing, or basic I/O, our engineers and technical staff has the expertise to deliver comprehensive designs that are top quality, well-managed, and on-time.

As a professional PCB and assembly manufacturer as well, we have better understanding of how to design a manufacturable, reliable and cost-effective PCB board than other suppliers. At MADPCB, you can enjoy one-stop PCB solution services from PCB design, PCB manufacturing to finished prototype and high-volume PCB assembly devices. Our mature engineering methodology ensures efficient, cost effective designs, done right the first time.

We offer 2 stage design reviews, either offline or interactive online. PCB designs can be provided using industry standard PCB design software:

- PADS (Mentor Graphics)

- Cadence (ORCAD & Allegro)

- Altium Designer (Altium)

We have extensive experience in creating RoHS compliant designs for new layouts and conversions of existing assemblies. Also, ask about our reverse engineering capabilities, as we can convert an existing PCB assembly without documentation into a complete and functional database.

Capabilities and Services Offered

- Schematic capture

- Assembly Drawings, fabrication drawings and Gerber files

- PCB layout from a customer provide schematic diagram

- Reverse engineering or clone from scratch PCB or PCBA

- Controlled Impedance (single, differential and hatch types) designs

- Layout for RF designs

- High Speed Backplane and Mid-Plane Designs (BGA, Microvia, Blind &Buried Vias)

- Multilayer PCB boards, split ground planes, differential pairs, high speed rules

- Routing per trace/space, keep-out (profile), and clearance rules specified by customer

- Component resequencing based on physical layout, reverse annotation to schematic

- DFT audit, test point placement, test probe clearance per customer rules, testability report

- Surface mounting or through hole (thru-hole) design

- Unusual PCB shapes.

Documentation Deliverables

- Read-me file with all relevant details and manufacturing guidelines

- Schematic (.pdf)

- PCB Netlist (.txt)

- Fabrication drawing (.pdf or Gerber format) -details must be provided by customer

- PDF copies of all PCB layer images

- Gerber files (format can be specified by customer)

- Rout and Drill files (Excellon format or specified by customer)

- Assembly drawing (.pdf or Gerber format)

- Centroid (.txt)

- BOM (.xls, or .xlsx)

- Any other customer specified outputs

Terms and Conditions of PCB Design Services

PCB design quotes are provided after studying the necessary input documents. Following documents are required for quote:

- Schematic

- Netlist

- BOM

- Mechanical Specifications

Feedback Reviews and Changes

Once the project is started, after receiving the required input documents, we will provide you the component placement drawings in PDF format. It is customer’s responsibility to ensure that the component placements and its footprints are satisfactory. Based on the feedback, we will update the component layout and complete the routing. The routing documents are again provided as pdf documents or Gerber files. Customer at that stage can approve the design based on the documents sent.

Once the customer accepts the project, a tentative project schedule will be given with anticipated dates for component placement, and routing approval and total project timelines. At any point of design cycle, if the design requires advanced techniques such as impedance matching, signal integrity (SI) checks, thermal simulations, revised project cost and timelines will be offered to the customer for their approval.