What’s Bluetooth?

Bluetooth is a short-range wireless technology standard that is used for exchanging data between devices over short distances using UHF radio waves in the ISM bands, from 2.402GHz to 2.48GHz, and building personal area networks (PANs). It was originally conceived as a wireless alternative to RS-232 data cables. It is mainly used as an alternative to wire connections, to exchange files between nearby portable devices and connect cell phones and music players with wireless headphones. In the most widely used mode, transmission power is limited to 2.5miliwatts, giving it a very short range of up to 10 meters (30 feet).

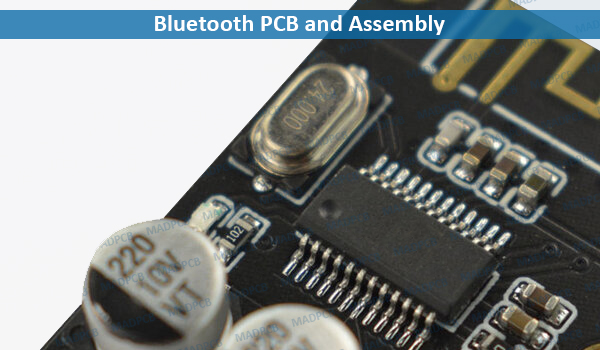

Printed circuit boards with built-in Bluetooth technology have a wide application nowadays.

Bluetooth vs Wi-Fi (IEEE 802.11)

Bluetooth and Wi-Fi (Wi-Fi is the brand name for products using IEEE 802.11 standards) have some similar applications: setting up networks, printing, or transferring files. Wi-Fi is intended as a replacement for high-speed cabling for general local area network (LAN) access in work areas or home. This category of applications is sometimes called wireless local area networks (WLAN). Bluetooth was intended for portable equipment and its applications. The category of applications is outlined as the wireless personal area network (WPAN). Bluetooth is a replacement for cabling in various personally carried applications in any setting and also works for fixed location applications such as smart energy functionality in the home (thermostats, etc.).

Wi-Fi and Bluetooth are to some extent complementary in their applications and usage. Wi-Fi is usually access point-centered, with an asymmetrical client-server connection with all traffic routed through the access point, while Bluetooth is usually symmetrical, between two Bluetooth devices. Bluetooth serves well in simple applications where two devices need to connect with a minimal configuration like a button press, as in headsets and remote controls, while Wi-Fi suits better in applications where some degree of client configuration is possible and high speeds are required, especially for network access through an access node. However, Bluetooth access points do exist, and ad hoc connections are possible with Wi-Fi though not as simply as with Bluetooth. Wi-Fi Direct was recently developed to add a more Bluetooth-like ad hoc functionality to Wi-Fi.

Bluetooth Technology and Applications

Printed circuit boards (PCBs) with Bluetooth technology can be problematic with interference, lost data and poor signal integrity if certain precautions aren’t taken. We’ll outline many rules and guidelines to consider when choosing Bluetooth technology for a given application and, more specifically, designing it into a circuit board.

A variety of applications utilize Bluetooth, including:

- Beacons used in unmanned supermarket

- Eddystone frames for industrial sensing applications

- Headsets and audio /stereo products

- Remote peripheral devices, such as video game controller or computer mice/keyboards

- Home automation systems

- Wireless consumer electronics applications, including cameras, printers and earphones

Each application incorporates the same common Bluetooth technology, but utilizes it differently and depending on the connector type, it’s up to the design engineer to incorporate basic principles to optimizing signal integrity and overall device effectiveness. Bluetooth is not a very fast wireless choice when compared to Wi-Fi, however, it is getting faster. It also doesn’t do well through walls and other nearby obstructions and has a poor image.

It is still a good choice, despite being a work-in-process (5.0 is the most recent update and is a decent improvement over 4.2). For the most part, it is fairly low-power, reliable, secure, widely supported option that can easily be implemented on a wide range of small peripherals.

Bluetooth has been around for 20+ years and is still evolving and although it’s improved in speed, power, range, security and other attributes over the years, it still seems to have some of the same issue since it’s conception in the mid-90’s, including its susceptibility to signal interference.

So, what can be done from a PCB design standpoint to optimize signal integrity, minimize interference and lost data packets?

Bluetooth PCB Design Considerations and General Rules

Adopt Certified Modules

If you’re incorporating Bluetooth into a product and are limited on resources, consider using a pre-certified, fully contained module to help accelerate development and time to market. It may drive cost a little in the end but will usually prevent several headaches that can rise from antenna placement/design and EMI susceptibility.

There are several reasonably priced certified modules in the market today and most incorporate a small RAM processor. Having the processor on-board gives it more flexibility and power, in addition to its Bluetooth stack.

Select Bluetooth Device

Make sure you’re choosing an appropriate Bluetooth device for the application and that the antenna has also been appropriately sized and tuned.

If you’re going for a simple beacon application where you only need to advertise location or date in short spurts/intervals, then a low-power (Bluetooth Low Energy or BLE), cost-effective solution with minimal features and peripherals could be used to save on-board real estate and end cost.

If you’re looking for more of a higher throughput, audio-streaming or data-exchanging Bluetooth application, then you may need something that has a bit more Tx power, higher Rx sensitivity and a faster data-rate (although slowing down the data rate can typically help with minimizing dropped packets).

If you’re looking for a sort of all-in-one chip, consider using the chipsets containing powerful or secondary processors that include available UART, SPI, I2C, PWM, ADC, DAC and GPIO pins.

If you’re working on something heavily dependent on an RSSI reading, make sure it has enough dB resolution on its RSSI monitor.

Separate or Remove Copper Signals & High Energy Components

When designing in a Bluetooth chipset or module, keep the antenna region completely free from nearby copper signals or components carrying significant amounts of energy (especially power paths that are switched, such as boost or buck converters).

This also includes keeping the area (and board layers) free of planes and polygon pours. Most Bluetooth chipset manufacturers will provide layout guidelines that should be followed closely during PCB design. If you’re manually laying out the antenna area, use a ground plane as appropriate to keep a good bandwidth at the input and make sure to build in enough room for tuning elements (a ground plane is required for printed and ceramic antennas).

Use ground stitching vias to prevent unwanted radiation from the PCB edge as it could penetrate nearby Bluetooth signals. If you can, try to make the board shape optimized to the Bluetooth device and where antenna is, keeping on the edge and far away from nearby components and signals. If using analog-based signals, such Audio, make sure that the analog and digital ground planes are separated.

And it’s always a good idea to shield the electronics (not the antenna of course) to prevent cross-coupling and minimize noise picked up.

Power Supply Notes

Make sure that the rail supplying power to the Bluetooth module or chip is clean and use bypass (1.0μF) and decoupling capacitor (0.1 μF and 10nF) where needed. Also feel free to use ferrite beads on the power rail entering the Bluetooth area of the circuit board to reject high frequency noise.

Tools and Analysis

If you’re designing the antenna area, make sure you have the proper equipment (such as a network analyzer) to analyze and tune the matching network, or consider sending the design to a 3rd party RF test lab.

Consider Real Obstructions

There are a wide variety of things that can cause obstruction or de-tuning during a Bluetooth connection, including nearby water, metalized objects, smart phones/tablets, computers, devices operating on the same ISM band, such as microwave ovens or WLAN technologies, power sources, wireless RF video, office lighting and home phones.

It’s hugely susceptible to signal loss even when paired at close distance (1-2 meters). If there is higher risk of these kinds of things impacting signal quality, then choose a higher power device and operate at a slower speed to minimize packet drop. Or if the electronics are inside of an enclosure, make sure that the metalized materials are minimized and far away from the BLE module. The relationship between Bluetooth signal strength and distance is not a linear relationship. In fact, it’s very non-linear and somewhat unpredictable based on the surrounding environment but does follow a general pattern.

Whether the expansion of Bluetooth PCB assembly, it’s an exciting time to incorporate wireless communication and control into products, and the future will only bring smaller, faster, cheaper and stronger Bluetooth components.

At MADPCB, we’re excited to help bring these new concepts into reality. Partnering with an experienced turnkey PCB assembly supplier with engineers that have long-standing relationship with component suppliers is crucial to the success of your next Bluetooth PCB fabrication and assembly needs.