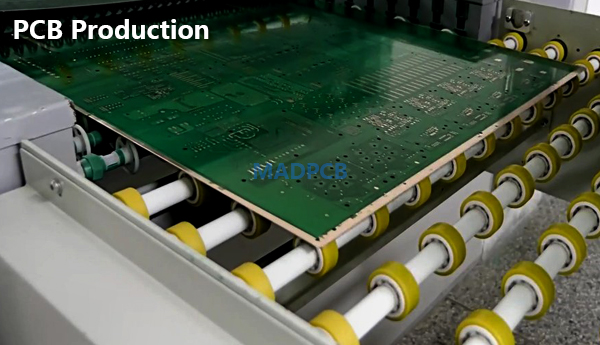

Are you planning for high-volume, large quantities PCB production for your products after prototyping verification? MADPCB has built its good reputation for years for domestic and overseas customers and beyond as the printed circuit board (PCB) manufacturer to trust from express PCB prototype and reliable PCB production services. We have capabilities to produce 1-30 layers rigid boards, 1-8 layers flexible printed circuits (FPCs), 2-20 layers rigid-flex boards and 1-4 layers metal core PCBs (MCPCB) with or without laser drilling microvias technology. As a China all-in-one PCB solution provider, MADPCB also provides PCB design, assembly, functional testing and reverse engineering services for customers who have unique or multiple service demands. For a world-class manufacturer of mission-critical, high-reliability, and time-sensitive products, look no further than MADPCB, which is a well-respected, well-known brand in the complex manufacturing process of printed circuit boards.

Standard and Special PCB Production

We have extensive standard and special PCB production process solutions for co-efficient of thermal energy (CTE) constraint, thermal management challenging designs and applications, extreme and unique high-density interconnect (HDI) structures, and high frequency (/radio frequency -RF) manifolds. Our PCB manufacturing capabilities enable us to provide application specific products as the following:

- Conventional PCBs

- FPC & Rigid-flex boards

- Rogers PCBs

- Metal Core PCBs (MCPCB)

- Halogen-free PCBs

- Edge-plating, hard gold, castellated hole PCBs

- Embedded PCBs

- Laser direct Imaging (LDI)

- YAG laser etching

- CO2 laser drilling

- Laser sculpting/profiling

- Multi-level cavity construction

- Composite/hybrid construction

- Asymmetric construction with various copper weights

Advanced PCB Manufacturing Capabilities

With years of expertise in high-precision PCB manufacturing no matter prototyping and large-scale production, we are capable of providing you a diverse advanced list of manufacturing capabilities that enable us to fabricate your complex PCBs.

- 2mil trace width and spacing

- 4mil laser micro-via

- 6mil chip-on-board

- 6mil mechanical NC via

- 7 via protection types (tenting, filling, via-in-pad)

- Backdrilling

- Sequential build-up (SBU) lamination

- Mixed dielectric constructions

- Core-to-Core lamination

- Silver and Carbon ink

- Heavy copper

- Thermal vias

- Blind/buried vias

- Microvias (stacked, staggered, skip)

PCB Materials Available – CCL, FCCL, PP, Adhesive, RCC, Copper Foil &EMI Shielding Film

We keep all varieties of PCB materials, including rigid and flex copper clad laminates (CCL), prepregs (PP), FPC used adhesive, HDI boards used resin cladded copper (RCC), copper foil and EMI films in stock, and work with them for meet any of your various PCB production requirements. Some of the materials features with low Dk (Er), low loss, high temperature, high thermal conductivity, low CTE, lead-free, halogen-free and more. We also produce circuit boards with RF/digital hybrid construction, combination of surface finishes (like ENIG + OSP for fine pitch components), stacked/staggered/skip solid copper-filled microvias, and impedance control on rigid boards and hatch impedance control on flex PCBs.

Strict Testing for High-Quality PCBs Delivered

We provide extensive testing of viable materials, surface coatings, and PCB constructions that have been validated by industry specifications to ensure that the printed circuit boards (PCBs) are delivered in high-quality, high-precision and high-reliability, and those PCB boards assembled into your final products work as your expectations while in your budget. Our various list of PCB testing options is as following:

- Copper to dielectric adhesion and tensile testing

- Microsection sample testing finished copper thicknesses and hole wall copper thicknesses

- Thermal sample testing with tin solderability

- Dimensional measurement

- Hole sizes measurement

- Microvia dimple measurement

- Electrical testing short and open circuits

- Surface visual checking

- Microline and stripline impedance coupon measurement

- Bow and twist measurement

- FPC bendability testing

- Surface Coating Measurement

PCB production is a complex process based on large quantities relied on professional process techniques, advanced equipment and well-trained manufacturing team. MADPCB’s secret to success is how closely we integrate with our customers and how quickly we can get your PCB prototypes and production project started and shipped on time. Our expertise in circuit boards is not limited to PCB manufacturing, but extends to PCB assembly and PCB design. So, MADPCB has better understanding of your PCB demands and know what your expectations are. Our highly skilled engineers will partner with you to achieve great-value-than-cost perfection in your single-sided to multilayer PCB production. Finding no more but MADPCB for your PCB production service provider.