What’s High Speed Design?

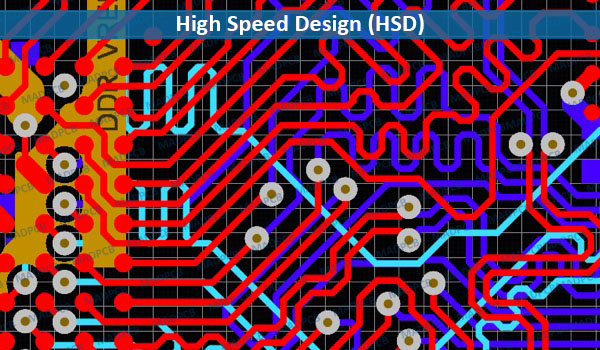

In PCB industry, High Speed Design, also known as HSD, which refers to a PCB design or layout is less susceptible to signal integrity, power integrity, and EMI/EMC problems, and the PCB can transmit data at a very high rate at certain frequency.

In high-speed design, any physical characteristics of your printed circuit board (PCB), like layout, SMD packaging, stack-up, interconnection, etc. could affect the integrity of your signals. When design such circuit boards and which run into problems, like delays, attenuation, crosstalk, reflections, or emissions, what your design is a high-speed design (HSD).

For ease of understanding, you also can identify high speed designs by certain characteristics, if:

- it uses HDMI, Ethernet, SATA, PCI Express, USB, Thunderbolt, or other high-speed interfaces for the fast data transfer;

- the circuit consists of several sub-circuits connected to each other through high-speed interfaces (LVDS, DSI, CSI, SDIO, DDR3, etc.);

- the time of signal propagation over the trace is at least 1/3 of the signal rise time;

- the digital signal frequency is of 50MHz and over;

- the size of the PCB is very small, and the location of the components becomes a real challenge (especially when you come across a high-speed interface layout).

In summary, high speed designs are applied to devices with PCBs working at high frequencies with the use of high-speed interfaces. With that, the amount of data and speed of its transfer mean a lot but not all.

But these are brief explanation about HSD. For figuring out the root of what the high-speed design is, continue to read more for following contents.

Is It High Speed Design?

If want to confirm whether a PCB design is high speed, or not, we follow 2-step processes:

Firstly, the system designers must state the values of one or more of the following parameters of design, which characterize the high-speed nature of the circuitry:

- The maximum frequency (Fm) content in the highest speed signals in the circuit.

- The fastest rate (or fall) time (Tr) of the digital signals in the circuit.

- The maximum Data Transfer Rate (DTR) applicable for signals in the circuit.

A PCB designer does not need all the above three parameters, even one will be sufficient, as it is possible to make an approximate estimate of the remaining two parameters by using the following formula:

Fm≈0.5/Tr≈2.5DTR

Our objective here is to determine the highest signal frequency content – Fm. Examples as following:

- Let the fastest rise time of the digital signals be given as: Tr=100ps (picoseconds). Then, Fm≈0.5/(100×10-12) ≈ 5x109Hz = 5GHz.

- Let the highest data transfer rate be given: DTR = 5.0GPs (Gigabits per second), then Fm ≈ 2.5 x DTR = 2.5×5.0x109bps =12.5GHz.

If the highest frequency content in the signals Fm is greater than 50MHz, it should be a high-speed design.

While the above rule is fine in most cases, there are special cases where even Fm = 60MHz may not need high speed design considerations, and there may be some cases where even 40MHz Fm may need high speed design care.

If want to be more certain, the designer can carry out the following additional steps:

Secondly, we need to determine the wavelength (λm) on the PCB of the electrical (electromagnetic to be precision) signals for a given frequency, in our case Fm.

Wavelength: λm = Vc/Fm

Signal Speed on Striplines: Vp (inner) ≈ Vc/√Er ≈ 11.8 /√Er

Signal Speed on Microstrips: Vp (outer) ≈ Vc/√Ereff ≈ 11.8/√Ereff

Where:

Vc=speed of signals on a PCB = 3×108m/sec =186,000miles/sec ≈ 11.8 inches/ns

Er is the dielectric constant of the PCB material

Ereff is the effective dielectric constant for microstrips; its value lies between 1 and Er, and is approximately given by:

Ereff ≈ (0.64Er + 0.36)

Propagation Delay Tpd = 1/Vc

Thus, the speeds of signals on a PCB is less than that in air. If Er≈4 (like for FR4 material types), then the speed of signals on a tripline is half than in air, i.e. it is about 6 in/ns. Henceforth, we can use Vp to denote the speed of signals on a PCB. Then, the propagation delay on PCB transimission lines is given by:

Tpd (strilines) ≈ 85√Er ps/in

Tpd (microstrip) ≈ 85√Ereff ps/in

The speed and propagation delay for some of the commonly used PCB materials are mentioned in the followint table:

|

Material |

Er (Stripline) |

Ereff (microstrip) |

Vc (microstrip) |

Vc (stripline) |

tpd (microstrip) |

tpd |

|

Vacum or Air |

1 | 1 | 11.8 in/ns | 11.8 in/s | 85 ps/in | |

| Isola 370HR | 4.0 | 2.92 | 6.90 in/ns | 5.9 in/s | 145 ps/in |

170 ps/in |

|

Isola I-Speed |

3.64 | 2.69 | 7.20 in/ns | 6.18 in/s | 139 ps/in | 162 ps/in |

| Isola I-Tera MT40 | 3.45 | 2.57 | 7.36 in/ns | 6.35 in/s | 136 ps/in |

158 ps/in |

|

Rogers RO3003 |

3.0 | 2.28 | 7.80 in/ns | 6.8 in/s | 128 ps/in | 147 ps/in |

| Rogers 4000 Series | 3.55-3.66 | 2.63-2.7 | ~7.20 in/ns | ~6.20 in/ns | ~139 ps/in |

~161 ps/in |

Knowing speed Vc from above chart, we can calculate the wavelength λm for a given frequency Fm.

If the length of an interconnection I <λm/12, then we do not need to consider it as a high speed interconnection. If I≥λm/12, then we do need to consider it as a high speed interconnection.

There is one caveat here: where mostly, we would be considering I here for the length of PCB interconnection, it may happen particular interconnection goes outside the PCB through a connector to a long cable; in that case, we need to consider the entire length of the interconnection.

Let’s Illustrate by Some Examples:

Assuming PCB material FR4 (370HR), we have Vc = 6.9 in/ns (microstrip) and 5.9 in/ns (stripline).

- For Fm = 50MHz, minimum λm = 5.9 in/ns / 50 MHz = 118 inch. Here Mininum λm/12 = 9.8 inch. Hence, if interconnection length I <9.8 inch, (which is likely to be the case if PCB size is <8’’ x 8’’) we may consider it as low speed, but if I ≥ 9.8 inch, which maybe the case for a PCB size of ≥ 6’’x8’’, we must consider it as high-speed one.

- For Fm = 100MHz, minimum λm = 5.9 in/ns /100 MHz = 59 inch. Here minimum λm/12 = 4.9 inch. Hence, if interconnection length <4.9 inch, (which is likely to be the case if PCB size is around 2’’x3’’) we may consider it as low speed, but if I ≥4.9 inch, which will be likely for a PCB size of around 4’’x5’’ or greater, we must consider it as high-speed one.

- For Fm ≥1 GHz, minimum λm ≤ 5.9 in/ns / 1 GHz = 5.9inch. Here Minimum λm/12 ≤ 0.5 inch. In any PCB, the interconnection length is likely to exceed this; Hence, we must consider it as high-speed one.

We thus see that the PCB size and therefore the interconnection length also play an important role in determining which interconnections are to be treated with high-speed design considerations.

Complexity of High Speed Design

In addition of high-speed considerations, we also need to asses the complexity of the design since it also requires special design considerations.

The prime factors that play a crucial role in the design complexity are:

- Component density (component count per board size).

- Routing density required.

- Pitch of high pin count devices like BGAs:

- Fine pitch BGAs (0.5mm, 0.4mm pitch) with >16 pins count. These invariably require blind and buried vias for proper I/O fanouts.

- Number of pins in a BGA exceeds 250.

- Types of interfaces: HDMI, Gigabit ethernet, DDR3, etc.

- PCB technology to be used:

- Small form factor board (1’’x1’’) with more than 50 components.

- Larger size boards with more than 500 components.

- Designs requiring impedance control 100ohm differential lines, 50ohm single-ended lines, and more than 500 components.

- Any design which takes more than two weeks to layout.

- The density of component pins exceeds 110 pins per square inch (17 pins per square cm).

- The density of component parts exceeds 10 parts per square inch (1.55 per square cm).

- The circuit requires mixed technology of digital, radio frequency (RF), or analog.

- The board requiring mixed materials for construction.

- The board has which has stringent electrical constraints.

- Boards having layers 8 to 12 multillayers or more, depending on the complexity.

High Speed Design Considerations

There are special considerations one needs to take when designing a high-speed PCB:

- All high-speed interconnections need to be designed as transmission lines and not just to point interconnections to reduce signal distortion, crosstalk and electromagnetic radiation.

- All causes of signal degradations need to be kept under control within acceptable limits.

- Adequate PCB technology is to be chosen so as to meet the demands of component density, wiring density, communication protocols, and complex devices.

- All causes of unacceptable levels of electromagnetic radiation need to be kept under control.

- Adequate power integrity has to be maintained in spite of high-frequency noise on power and ground rails in high-speed circuits -ensuring adequate power supply voltages are maintained at all the electronic devices and components for them to function properly.

- Adequate and special PCB routing schemes need to be adopted to meet the demands of component density, wiring density, communication protocols, and complex devices.

The first threes of the above points are usually covered under the disciplines called Signal Integrity and PCB Stack-up Design, the fourth point is covered under the discipline called EMI, the fifth is covered under Power Integrity, and the sixth under Special Layout Routing Techniques.

High Speed PCB vs. High Frequency PCB

When it comes to the terms High Speed PCB and High Frequency PCB, people often think that they are the same, but in fact, the meaning of the two is completely different.

- High speed usually refers to digital technology that transmits data at a very high rate, which is related to the time domain.

- High frequency is usually related to the radio frequency (RF) of the analog signal at high frequency moving energy, which is how electromagnetic waves respond in a specific frequency or range of frequencies, related to frequency.

However, there is also a fundamental relationship between High-Speed Digital (HSD) signals and High-Frequency (RF) techniques. For example, pulses for digital information transmission are generated by RF waveforms. Basically, a sine wave can be thought of as an RF waveform. When several sine waves of different frequencies are combined, they can form a square wave, and a square wave can generate a pulse of a digital signal. As a simple example, the 2GB/s digital pulse speed (clock speed) is formed by RF signals at frequencies of about 1GHZ, 3GHZ, 5GHz, 7GHz etc., sorted by a given frequency, respectively, at the fundamental frequency (1GHz). The fundamental frequency three times harmonic (3GHz), five times harmonic (5GHz) and seven times harmonic (7GHz) frequencies.

When designing a PCB at millimeter-wave frequencies, the wavelengths associated with PCB design characteristics are important, and wavelength segments can affect circuit performance. A stripline PCB with a material DK of 3 is used, which has a wavelength of about 0.100’’ (2.54mm) at 70GHz. When the circuit characteristics are about 1/2 of the wavelength, the waveform performance is significantly affected, even at 1/4 of the wavelength, there is also an effect; the negative effect of this feature on the waveform performance can be avoided when it less than 1/8 wavelength. For example, the physical dimension of the strip line associated with 1/8 wavelength at 70GHz is 12.5mil (0.32mm). Basically, any signal greater than 1/8 of the wavelength will affect the performance of the 70GHz waveform, and simply getting energy from the connector can be a problem.

Wavelengths at millimeter wave frequencies can affect circuit performance, while material properties can affect the RF performance of the circuit. Most materials used in high frequency PCBs have a woven glass reinforcement to increase the mechanical stability of the material.

Commonly used high frequency materials are Rogers series high frequency PCB material, click the link High Frequency PCB Material. Commonly used high speed materials are TU875, TU872SLK, R5725 (M4), S7439, FR408HR, R5775 (M6), IT150DA, EM370D and so on.