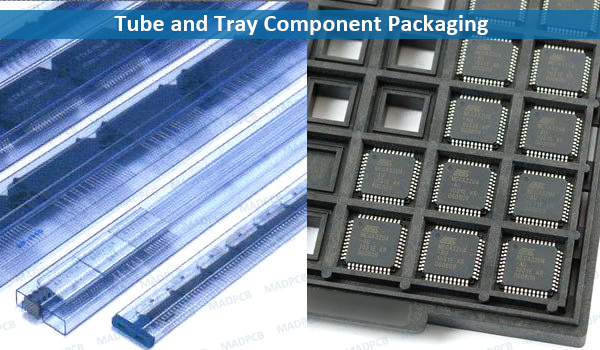

Tube and Tray Component Packaging styles are similar in that they allow for the safe storage and transport of larger parts that do not fit comfortably in Tape-and-Reel Packaging. Compared to Loose and Bulk Packaging, where the components are stored loose in a bag or box, Tube and Tray packaging is certainly preferable in terms of security during transportation. These packaging styles also allow for more efficient PCB assembly by MADPCB’s pick & place machines, so if you have the option to choose between Bulk or Tray / Tube packaging, it is highly recommended that you select the latter in nearly any circumstance.

Tube

Tubes (also called stick magazines) are one of the first types of shipment packages. They are used for both SMD and THD components.

Tray

Trays are used for shipment and handling SMD packages. Tray’s advantage in regards to tube packages is that they protect balls and leads from mechanical and electrical damage.

Standard Tray Dimension by JEDEC is 322.6 x 136mm (12.7 x 5.35 inches). There are 2 standard JEDEC tray thicknesses:

- Low profile of 6.35mm (0.25 inch) suitable for BGA, CSP, QFP, TQFP, SQFP, TSQFP, QFN, SOP, TSOP, TSSOP and SOIC

- High profile of 10.16mm (0.4 inch) suitable for CERAMIC QUAD, PGA, and PLCC

Both Tube and Tray packaging describe a storage system where a plastic carrier is used to hold your electronic components in such a way that they are isolated from one another as well as the outside environment. This might seem like a minor advantage to those used to dealing with bags of parts in the lab on a day-to-day basis, but the added protection of that plastic shield can work wonders for component durability during shipping and receiving. This added durability allows for lower levels of production loss, and the end result is that fewer components must be purchased for the same number of finished boards.

Thanks to MADPCB’s flexible and efficient PCB assembly process, your procurement order (PO) will not see any increase in cost or turnaround time due to the presence of tube or tray packaged components, compared with common tape and reel parts.

Altogether, Tray and Tube packaging are a great option for those larger components, in terms of both security and efficiency. From both the client’s and the PCB assembly service provider’s point of view, it is fairly unquestionable that these packaging styles are superior to the simpler bulk packaging method.