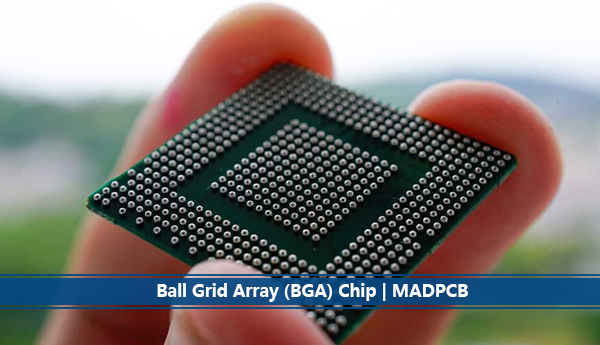

Ball Grid Array (BGA) is a type of surface-mount packaging (a chip carrier) used for integrated circuits. BGA packages are used to permanently mount devices such as microprocessors. A ball-grid array can provide more interconnection pins than can be put on a dual in-line or flat package. The whole bottom surface of the device can be used, instead of just the perimeter. The traces connecting the package’s leads to the wires or balls which connect the die to package are also on average shorter than with a perimeter-only type, leading to better performance at high speeds. Soldering of BGA devices on printed circuit board requires precise control and is usually done by automated processes.

| Ball Grid Array (BGA) Packages | ||

| Acronym | Full Name | Remark |

| FBGA | Fine-pitch ball-grid array | A square or rectangular array of solder balls on one surface |

| LBGA | Low-profile ball-grid array | Also known as laminate ball-grid array |

| TEPBGA | Thermally-enhanced plastic ball-grid array | – |

| CBGA | Ceramic ball-grid array | – |

| OBGA | Organic ball-grid array | – |

| TFBGA | Thin fine-pitch ball-grid array | – |

| PBGA | Plastic ball-grid array | – |

| MAP-BGA | Mold array process – ball-grid array | – |

| UCSP | Micro(μ) or Ultra chip-scale package | Similar to a Ball-Grid Array |

| μBGA | Micro ball-grid array | Ball spacing less than 1mm |

| LFBGA | Low-profile fine-pitch ball-grid array | – |

| TBGA | Thin ball-grid array | – |

| SBGA | Super ball-grid array | Above 500 balls |

| UFBGA | Ultra-fine ball-grid array | |

Are you finding a turnkey PCB assembly manufacturer to complete your prototype or high-volume PCB assembly projects? Any motherboard with BGA assembly requirements, think twice before submit your job to any supplier. Just consider us, MADPCB.